Toyota Joins Japanese Companies to Create Carbon-neutral Hydrogen Supply Chain

Major corporate and public sector partners in Japan have decided to work together to establish carbon-neutral supply chains across different sectors (from power generation to vehicle fueling.)

A new initiative was announced on Sept. 8 that aims to create a full-fledged carbon-neutral hydrogen supply chain powered by renewable wind energy.

According to the Intergovernmental Panel on Climate Change, nearly 25 gigatons of CO2 -- over half of the world's greenhouse gas emissions -- come from the use of fossil fuels in electricity and heat generation, industry and transportation.

While hydrogen is most commonly created through a reaction between methane and steam, it can also be created from water through electrolysis. More often than not, this requires electricity―which is still typically produced using fossil-fuel-burning power plants. Since the overall environmental benefit of hydrogen is only as strong as the method used to produce it, global research initiatives around the world are dedicated to developing large-scale carbon-neutral projects that use renewable energy to power hydrogen production.

The four private sector participants are Iwatani Corp., Toshiba Corp., Toyota Motor Corp., and Toyota Turbine and Systems Inc.

On the public sector side, the project is being implemented by the Kanagawa Prefectural Government, Yokohama City, and Kawasaki City. In addition, the project will be supported by Japan's Ministry of the Environment.

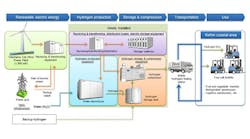

Under this trial project, wind power will be used to turn water into oxygen and hydrogen, with the latter stored for use locally. Grid power will only be used for backup when absolutely necessary and excess renewable energy produced may even be sold to utility companies.

As plans currently stand, the project will involve

- A system to produce hydrogen by electrolyzing water using wind power

- A system to optimize storage and transportation of hydrogen produced

- Use of fuel cell forklifts

- A hydrogen supply chain feasibility study (hydrogen price, CO2 reduction, etc.)

The total project duration is expected to take place over four years. At this stage, the project partners are still discussing specifics. Implementation is set to begin from April 2016 onward.