The Logistics Landscape Is Wide Open for the Internet of Things

Twenty billion. That's the estimated number of devices that will be connected to the Internet by 2020, according to analyst firm Gartner (currently, 5 billion connected things are in use). It's part of the global push behind what's known as the Internet of Things (IoT), defined by Gartner as "the network of physical objects that contain embedded technology to communicate and sense or interact with their internal states or the external environment." Taking that definition to the next logical step, the McKinsey Global Institute adds that IoT devices "can monitor their environment, report their status, receive instructions, and even take action based on the information they receive."

In other words, if and when IoT technology takes root and is applied where appropriate, the status of raw materials, components, production machinery, finished products, material handling equipment, packaging, and transportation vehicles—basically, the entire supply chain—can be known and communicated at any time, from any place.

Although the buzzword itself is new, the core concept to the IoT has been around for decades. As Steve Banker, vice president, supply chain management with industry analyst firm ARC Advisory Group, notes, the IoT is "nothing new in logistics." As far back as 1975, he points out, companies were taking radio-frequency scans and using that data to improve warehouse processes.

However, while the basic data collection technology has been in place for at least 40 years, it hasn't been leveraged to its full potential until quite recently.

As exciting as the potential of the IoT may be, though, the reality is that nobody can quite yet imagine what the killer apps will be for their industry, notes Greg Braun, senior vice president with C3 Solutions. But the consensus appears to be that, at least within supply chain circles, "end-to-end visibility has long been the holy grail" and that's where you'll find the earliest examples of IoT technology being deployed in the real world, according to Braun.

IoT in the Real World

Here are a few examples of how companies are using IoT to improve areas of their logistics operations:

- Nestlé, one of the world's largest food producers, has deployed wireless vehicle management systems (VMS) developed by I.D. Systems on more than 2,000 industrial trucks across more than 60 manufacturing and distribution facilities. The VMS automatically uploads vehicle data, reports vehicle problems electronically, and schedules maintenance based on actual usage. For Nestlé, the VMS helps ensure that only trained personnel have access to the vehicles, and that safety protocols are followed before the vehicles are operated. The VMS includes a smart impact sensor, as well as automatic shut-off functions when trucks are left idling, which helps reduce fuel consumption and emissions.

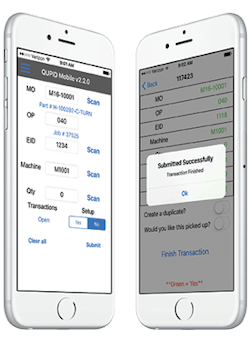

- Itamco, a manufacturer of gears and other precision-machined components, has connected its forklifts to the industrial IoT utilizing an MTConnect-enabled machine-monitoring program. After key pieces of machinery were connected to MTConnect (an open communication standard) and to the company's ERP system, Itamco developed a GPS-based communication system for its forklifts. Forklift operators are notified via their smart devices when they're needed, how many pallets need to be moved and where they should be taken. The IoT solution has improved forklift efficiency by 10%.

- Specialty chemicals giant Dow Chemical uses IoT technology to monitor the transportation and distribution of its high-risk and hazmat shipments, whether those products are moving by truck, train, or ocean carrier. Dow's risk management program incorporates various identification solutions (RFID, GPS, bar codes) as well as sensor technology to monitor security of the cargo as well as environmental conditions while in transit.

All that being said, a healthy amount of skepticism still exists among industry as to the need for IoT, and certainly the thought of investing heavily in yet another "paradigm-shifting" technology is responsible for many corporate managers to hit the "pause" button. According to a study conducted by LNS Research, nearly half of respondents (46%) say they do not expect to invest in IoT technologies in the foreseeable future, another 18% don't expect to invest in IoT for at least a year, and 16% might invest soon but don't actually have a budget yet. That leaves only 20% of the potential user base as actively pursuing IoT for business purposes (and only 2% say they've already made significant investments in the technology).

Even so, the number of fence-sitters will likely decrease as more and more real-world success stories are publicized. Inevitably a cottage industry of solution developers and service providers has already emerged, with the more spurious promising to do anything and everything. But while you dodge the entreaties of the Internet of Snake Oil evangelists, pay attention to what your competitors are doing with the technology, and just as importantly, listen to what your customers are asking for.

Sensors, asset management and identification technology may not be new, but the ways companies are incorporating these tried-and-true tools into smart applications could very well change the nature of logistics management in the coming years.

About the Author

Dave Blanchard

Senior Director of Content

During his career Dave Blanchard has led the editorial management of many of Endeavor Business Media's best-known brands, including IndustryWeek, EHS Today, Material Handling & Logistics, Logistics Today, Supply Chain Technology News, and Business Finance. He also serves as senior content director of the annual Safety Leadership Conference. With over 30 years of B2B media experience, Dave literally wrote the book on supply chain management, Supply Chain Management Best Practices (John Wiley & Sons, 2021), which has been translated into several languages and is currently in its third edition. He is a frequent speaker and moderator at major trade shows and conferences, and has won numerous awards for writing and editing. He is a voting member of the jury of the Logistics Hall of Fame, and is a graduate of Northern Illinois University.