Omni-channel fulfillment is increasingly becoming the norm for manufacturers, retail suppliers and retailers due to growing demand to fulfill a wide variety of order requirements ranging from single-line orders to full-trailer shipments. Orders within the same operation can come from multiple sales channels: Internet/direct to consumer, specialty boutique stores, direct to big box retailers, and to other distributors.

Omni-channel order fulfillment requires a detailed plan that considers all of the dynamics required to balance workloads and efficiently process orders in a parallel simultaneous pick and pack operation for each unique order fulfillment channel. Order release becomes the throttle of the operation and requires the right software algorithms to intelligently manage the order mix to meet customer type, delivery time windows and ensure a continuous order flow to avoid bottlenecks and obtain optimum throughput across the pick, pack and ship processes.

Orchestrating Omni-Channel

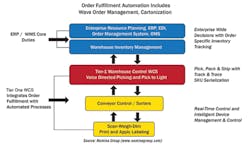

Core strengths of enterprise resource planning (ERP) and warehouse management systems (WMS) are managing receiving, inspection, inventory and replenishment within the warehouse or distribution center. The software needs for omni-channel pick, pack and ship processes require order release, labor balancing and management and managing and executing material handling automation technologies. Tier One warehouse control systems (WCS) are emerging as answers for omni-channel order fulfillment. They include automation components and a scalable software architecture to manage real-time order processing and control decisions.

Tier One WCS software platforms can move beyond the traditional WCS duties, such as middleware for the interfaces between the WMS/ERP and ASRS, conveyor, sorter controls and floor level PLC supervisory control. The Tier One WCS expands the definition of WCS, providing advanced picking automation and functionality developed specifically to provide higher performance order fulfillment process automation.

A Tier One WCS contains software automation modules to balance order release and work flow across picking, packing and shipping processes. It is more cost effective to fine-tune a WCS to the specific processes such as specialty picking/packing rules for fragile items, providing gift wrapping for an Internet order, and optimizing the automation investment to specific business needs.

These modules include order release, order balancing, wave creation, cartonization, voice picking, pick to light, print and apply labeling and pack/ship automation. The software is designed to control the entire order fulfillment operation in a singular, continuous operation.

This enables high-volume operations to achieve high throughput and efficiency.

A Tier One WCS should incorporate the following functions:

- Provide an order fulfillment automation platform that controls and operates as a continuous-process that integrates and optimizes picking through shipping in real-time.

- Contain all the automation components fully integrated into one software platform including modules for controlling and managing picking, packing and shipping.

- Has a database architecture built to manage SKU Plus records for supporting serialized track-and-trace of both linear and 2D barcodes.

- Scalability to operate one or more pick-pack-ship lines within a distribution center (DC), as well as multiple additional pick-pack-ship lines in multiple locations external to the DC simultaneously.

Continuous-Process, Real-Time

Pick, pack and ship processes utilize an arsenal of automatic identification and data capture (AIDC) technology, such as barcode scanners, optical character recognition (OCR) and radio-frequency identification (RFID) to monitor the flow of goods through picking, sortation, conveying, scales, dimensioning systems, print and apply label applicators, packaging, robotics and other automatic machinery. These units need to capture and relay data to and from the WCS and other material handling equipment (MHE) in the system. In high-volume, high-speed distribution centers this transmitted data can represent millions of process transactions per hour.

A Tier One WCS encompasses all of the pick-pack-ship processes within its functionality, and, controlled as if it is one unified machine with real-time functionality, it can execute these throughput processes with the most efficient cycle times.

To ensure rapid processing speeds, a control language acts as a multi-function, event-based control engine that performs real-time control at speeds in the range of 100 microseconds. Real-time control tasks are managed in the operating system deployed on an industrial hardened PC-based controller using a wide variety of industry standard I/O devices, controlled and managed over an Ethernet control network.

Integrated Processes

A tier One WCS automation architecture covers everything from the field level and production control level, to diagnostics and reporting. It also provides interoperability, including everything from the controller, HMI and drives, to the process control system. Tier One WCS fully-integrates control and process management to reduce the complexity of the automation solution, and incorporates a redundant architecture to lower the risks of single point of failure.

Track and Trace SKU Serialization

The Food and Drug Administration’s (FDA) pending track-and-trace mandates for the distribution of pharmaceutical pallet, mixed-case and split-case product serialization require changes to current product labeling and barcode requirements. A standardized numerical identifier (SNI) will be required to be printed on item-level packages. The FDA’s SNI guidance prescribes an identifier that contains the National Drug Code, and a second 20-digit alphanumeric identifier that would be unique to a drug package. The SNI would be printed in a two-dimensional (2D) data matrix barcode, or alternately a radiofrequency identification (RFID) tag, on the immediate package as it goes down the packaging line.

Track and trace is essentially a collection of tools employed to make sure regulators and companies can determine the authenticity, identity and whereabouts of a particular product. Under an ideal system, regulators would be able to track where a product is going in the supply chain and trace where it has been.

A Tier-1 WCS, through its data field-linked database design, supports both a local and distributed database with large data elements, images and blobs for order/SKU data tracking requirements. Fields have the capability to link 128 alphanumeric characters or more for ID and track and trace requirements.

Tracking and traceability will be needed across wider product categories: consumer goods, electronics, nutritional supplements, health and beauty items and specialty foods.

A Tier One WCS can integrate a single, or multiple operations within a single distribution facility, as well as operate at remote or multiple locations. Supply chain and distribution executives looking to deploy leaner, low-touch automated fulfillment would be well served to investigate Tier-1 WCS to accelerate their operational profitability goals.

Jamie Alexander writes on logistics automation.