Explore All Your Options to Choose the Right Transportation Mode

The relentless onset of globalization and the ever expanding complex global supply chains that permeate the business world have accentuated the importance of carefully evaluating transportation modal choice decisions. As companies deploy their inventories across multiple countries and continents to serve growing markets, the costs of transportation itself, and just as importantly, the direct impact of transportation modal decisions on a company's inventory investment requirements and annual carrying costs requires closer scrutiny than ever before.

To avoid the trap of focusing strictly on freight costs, companies must employ a rigorous transportation mode choice decision-making methodology that recognizes all the costs associated with their transportation decisions. This article will look at a methodology which combines both annual cost and long-run investment perspectives to identify the best transport mode choice.

Many companies today still fail to evaluate thoroughly the true costs of alternative transportation options on their logistics network. And even those companies that do take into account all annual costs frequently fail to carefully evaluate the investment aspect of their transport mode decisions.

Case Scenario: By Air or By Ocean?

To illustrate our methodology, consider a hypothetical scenario in which a company must evaluate whether to ship product by air or by ocean between two of its facilities located on different continents (e.g., the Far East and the U.S). Before proceeding, we should also emphasize that the techniques presented here are generic in that one can apply them to evaluate the inventory investment and total cost implications for shipping product or materials by any modes between two locations (e.g., truck vs. rail, or even two truck alternatives with different transit times and costs per unit).

Our hypothetical example assumes that a company manufactures finished goods inventory (FGI) in a plant in the Far East and distributes these products to customers in Europe from its logistics center located somewhere in Europe. We further assume that the company supplies make-to-stock products on demand to its customers from this logistics center. Thus, it must maintain inventory at the logistics center to fill orders immediately as customers place them, and it must maintain a safety stock or buffer inventory to cover the variability in demand over inventory replenishment lead time, and the variability of replenishment lead time. The question the company must now answer is whether to ship FGI from its plant to its logistics center by air or by ocean.

Key Costs to Evaluate

To evaluate whether to establish air or ocean inventory pipelines to transport the company's products between its plant and logistics center, we must consider five major cost factors which will differ depending upon which transportation mode the company selects. These are:

- freight costs,

- the inventory carrying costs of inventory in the pipeline,

- the inventory carrying costs of cycle stock at the receiving logistics center,

- the inventory carrying costs of the required safety stock at the receiving logistics center,

- the investment cost required to produce the inventory to fill the pipeline (i.e., the average total inventory required in transit and at the logistics center).

The first four cost factors are annual recurring costs which will continue as long as the transportation inventory pipeline exists, while the fifth cost represents a one-time cost required to initiate the pipeline.

Integrating Inventory Investment Analysis and Annual Costing

The annual costs can be analyzed using traditional spreadsheet calculations once the proper supporting data have been developed. However, calculating the initial inventory investment and determining the return on investment associated with an inventory pipeline modal choice is not as straightforward. Investment decisions typically involve weighing an expected return against the investment necessary to generate that return. In other words, to evaluate the pipeline modal choice from a long-term investment perspective, a company must quantify both the investment and the expected return associated with each mode.

The best way to do this is to focus on incremental costs and investment, determining whether the annual savings in transport costs from an ocean pipeline justify the incremental investment in inventory needed to build it, i.e., the ocean pipeline inventory investment less the air pipeline inventory investment. This approach views the annual incremental savings or cost avoidance associated with ocean transport as the incremental stream of income resulting from the incremental investment in an ocean pipeline. An ocean pipeline will, of course, always require a larger initial inventory investment than an air pipeline because the transit time—and hence days of inventory—is longer.

With the incremental annual stream of income and the incremental pipeline investment defined, one can now calculate standard measures for evaluating the alternatives, such as return on investment and the investment payback period.

Exposing Vulnerabilities

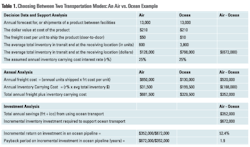

Table 1 illustrates both the annual cost and the investment analysis of our hypothetical scenario. The "annual analysis" section indicates that utilizing an ocean pipeline to transport the company's product from its Far East plant to its European logistics center will save $352,000 per year. The higher annual inventory carrying costs ($168,000) resulting from the longer transit time of ocean passage are outweighed by the substantially higher freight savings ($520,000) yielded by ocean.

The "investment analysis" section of Table 1 evaluates the ocean vs. air decision from two perspectives: return on investment, and the payback period of the investment. Dividing the annual savings ($352,000) generated from using ocean by the incremental inventory investment ($672,000) required to support ocean produces a 52.4% return on the incremental inventory investment. To project the number of years it will take for the additional inventory investment required by ocean to "pay for itself," we divide the incremental inventory investment ($672,000) by the annual "ocean" savings ($352,000). This calculation shows that in just under two years (1.9), the savings generated from utilizing ocean transport will pay for the incremental inventory investment. This provides an important perspective for the decision-maker.

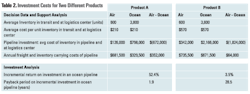

To illustrate this further, consider Table 2, which summarizes an annual cost and investment analysis for two products. Product A (which has a unit cost of $210) is the same product evaluated in Table 1, while Product B ($570 unit cost) is a second, more expensive product that our fictitious company produces in the Far East and ships to its logistics center to serve European demand.

Table 2 shows that the ocean option represents the cost-minimizing alternative for both products B ($64,000 annual savings) and A ($352,000). Importantly, however, from an incremental inventory investment perspective, the savings for product B from an ocean pipeline generates only a 3.5% annual return, and further, would require over 28 years to pay for itself. The additional perspective offered by the investment analysis strongly suggests that the annual savings generated by an ocean pipeline for product B would not justify the required extra inventory investment.

A company that only considers the annual costs of transport mode alternatives, and which neglects the investment component of this decision, is far more vulnerable to making poor transport mode choices (e.g., selecting ocean transport for product B).

Critical Points to Consider

Although the actual calculations required to evaluate alternative transport pipelines are straightforward, developing and analyzing all the necessary data are difficult challenges requiring a rigorous methodology. Critical guidelines to facilitate successful results include the following. Companies must:

- evaluate the total logistics network costs of a pipeline transport mode decision, incorporating, for example, the impact of modal choice on a logistics center's safety stock requirements;

- evaluate pipeline transport mode decisions from both an annual cost and an inventory investment perspective rather than focusing on just annual costs, or even worse, focusing on just freight costs;

- evaluate other costs where pertinent, such as the potential salvage value of an inventory pipeline;

- conduct sensitivity analysis on their initial quantitative results to determine how results (and decisions) may change under different scenarios, such as variations in assumed inventory carrying cost interest rates, fluctuations in freight rates, and so on.

In conclusion, the methodology presented here for performing an air vs. ocean pipeline is generic and should be applied to any transport mode choice decision for shipping products or materials between two locations. Further, one can easily enhance this methodology to incorporate any special cost factors (e.g., pipeline salvage value) which may vary by mode, and which are relevant to a specific mode choice decision or case. Finally, one can enhance the investment analysis illustrated in this article to include other measures such as net present value, if appropriate.

Tan Miller is director of the Global Supply Chain Management Program at Rider University, College of Business Administration, and a member of the MH&L Editorial Advisory Board. For a more in-depth discussion of the topics covered in this article, consult Miller’s book Strategic Logistics (2006, Thomson Reuters).

About the Author

Tan Miller

Director, Supply Chain Management Program

Dr. Tan Miller is director of the Global Supply Chain Management Program at Rider University, College of Business Administration. His responsibilities at Rider include advising students in the GSCM Program, teaching introductory and advanced courses on supply chain management, and directing ongoing enhancements to the GSCM curriculum. Previously he worked in private industry for over 20 years where most recently he was responsible for the operations of J&J’s U.S. Consumer Distribution Network. Prior to that, he headed the U.S. Consumer Healthcare Logistics Network of Pfizer Inc., and he has also held production and distribution management positions with Mercer Management Consulting, Unisys, Warner-Lambert and American Olean Tile Company. Miller has published five books and over fifty articles, and has made over 100 industry and academic conference presentations on supply chain and logistics operations and planning. His most recent books include Supply Chain Planning: Practical Frameworks for Superior Performance (Business Expert Press), Hierarchical Operations and Supply Chain Planning (Springer-Verlag Publishers) and Strategic Logistics: Efficient Transportation Decisions (Boskage Commerce Publications). Miller has also taught part-time in the MBA program of Villanova University, has guest lectured regularly at other universities and industry conferences, and has served on the editorial and advisory boards of a number of trade and educational journals and councils. Tan received an M.A, M.B.A and Ph.D from the University of Pennsylvania.