Compete: Site Selection - Labor of Love, Not Game of Luck

Fashion trends and site selection criteria are similar—what's popular this year may not be the hottest thing next year; and definitely not in the next five years. For many companies the effects of geopolitical events, market changes, labor costs and energy costs on their distribution networks remain top concerns, especially as site selection criteria. That's why site selection philosophy needs to shift toward building a robust and flexible distribution network, which can help alleviate or adapt to those future challenges.

The Big Picture

Before you throw a dart at a map to select a site, pause and reflect on the implications that the new site will have on your overall network and your company's go-to-market strategy. Remember supply chains are no longer just local; they span the globe, creating a smaller, flatter, more interconnected world. Consumers are fluid, market shifts are the norm rather than the exception and third-party logistics providers are more plentiful and capable than ever. In other words, to be responsive, companies need a robust distribution network of partners, not necessarily a perfect site. Even if the dart lands in Michigan, the prime site to modify in your distribution network may be Indiana, Wisconsin, or even Georgia when transportation flows, fuel costs, lease terms, facility size, growth projections and/or customer expectations are taken into account.

There is more to site selection than any one individual factor. Managers should ask questions about how a potential site will fit into their overall network flow. Will the site be responsive to changes in the market and what will the total network cost be to the company? Site selection begins with network design and as companies reconsider their network, they should make sure it aligns with the company's go-to-market strategy and that it fits into a strategic supply chain context.

What to Consider

Oscillating energy costs, new laws and regulations, fewer state and local incentives due to the economic situation (states and cities have less money these days), and an aging infrastructure have corporate managers rethinking their strategy for site selection. While no company has control over the cost of fuel, what laws or regulations Congress or states will enact, state and local incentives, unexpected geopolitical events, or overall infrastructure issues, it does have control over the design of its distribution network. By creating a flexible, robust distribution network that takes a long-term view, you can alleviate potential problems—and gain facilitating friends in the bargain.

To create a robust distribution network, first look at the individual warehousing and distribution centers to determine whether those sites fit into your overall network flow and overall company's go-to-market strategy. Before adding to or moving a site to create a network that is more robust ask yourself a few quick questions:

• What markets will the new site serve?

• Should the site be a larger facility that supports multiple regions or should we build more warehouses or distribution centers that are smaller and closer to customers?

• What are our transportation options at those new sites, especially if our customers decide to change their delivery strategy?

• What is the political stability of the region? How will that affect transportation/multi-modal options for our customers?

• What is our service-to-the-market strategy likely to be in the future: 3-day, 2-day or same/next day?

• Will our client's order patterns change to require more frequent and smaller shipments to reduce inventory at their end of the supply chain?

Know the Neighbors

Figuring out what markets you will serve can be as easy as looking at a map or as complicated as hiring a site selection consultant to perform a service area study. The easy route is taking the time to call and discuss issues that other area warehouses and distribution facilities are having. Ask them why they are there, what is the transportation infrastructure like and if they are meeting the cost and service targets that were set before they located to the area.

If you are worried about reaching out to other distribution facilities in the area, don't be. There are plenty of opportunities to speak with representatives from those sites. Begin a discussion on a social networking platform like Facebook, LinkedIn or Twitter. Attend local professional meetings hosted by WERC, NAIOP, CSCMP, etc. Attend a national conference hosted by one of the professional organizations. One reason to attend local meetings and conferences, especially in the logistics and supply chain field, is to discover best practices or issues and concerns that could infect your distribution facility. Another reason is to be able to benchmark against competitors. Local meetings and conferences provide the best opportunity to "snoop around" without really snooping.

Keep your transportation options open. Look for sites that provide a mix of options from air and rail to truck and ocean shipping. Your customers' business strategies are changing as fast as teenagers. If your customer changes plans a year after you start operations and expects you to deliver to another region in the country or to another country altogether, can you receive and send shipments using a combination of shipping methods?

And don't forget about the potential to expedite orders. While FedEx and UPS have their place in supporting your strategy, the cost of this service must be included in your total cost analysis. Being located near a combined heavy weight/small package air hub can make a difference.

Expect the Unexpected

Take a minute to understand any long term plans that could alter the mix of products and how that will impact your shipping methods and service delivery. Take into account geopolitical events, such as the tensions surrounding the Korean peninsula or changing regimes in the Middle East and North Africa, which may continue to have an impact on your transportation options into the future.

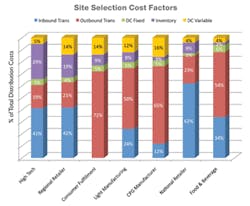

Remember that transportation is typically over 60% of the cost of a company's supply chain with labor running 4-16%. Rent, taxes, and maintenance are typically less than 6% of supply chain costs. As you can see in the above chart, the transportation component differs by industry vertical. In this diagram, you see it ranging from 60% of total costs for the average high tech company to as high as 88% for the typical food and beverage company.

Be sure to consider your company's growth potential as well, and with which customers. Will the business grow or decline over the next five years? Will it expand or reduce overseas operations? Will you focus more on the big box retailers or more on boutique retailers? Do you want to outsource your operations to a 3PL? Is your company willing to take on the risk of facility ownership vs. leasing? Having multiple smaller distribution facilities will speed delivery to customers and lower fuel and trucking costs, but it will be harder to manage the inventory and consolidate deliveries if something changes.

At the same time, don't fall into the one-size-fits-all approach. If your company provides a range of products and services, locating a large cold storage facility, for example, in a central location to support all those customers may make sense. The larger facility will have higher costs associated with transportation—longer routes, slower delivery, and higher fuel usage—but there may be lower total costs when taking other factors into consideration such as work force training, lower inventory levels, energy costs, and ability to consolidate orders. Be sure to consider the total landed cost when analyzing your network cost, not just one or two individual elements.

Final Thoughts

Your distribution network must be flexible to improvise, adapt and overcome any potential changes in the "New Normal" economy. Understanding that site selection decisions are based on cost/service tradeoffs and how those tradeoffs affect your overall network flow and total cost of ownership will help you make better informed decisions.

Remember there is no silver bullet in site selection. However, careful consideration of the total landed cost, energy availability, geopolitical impacts, incentives, infrastructure and fellow stakeholders in light of current and future needs—while keeping the overall network design in mind—will enhance your ability to find the right site for your next distribution facility.

Tim Feemster is managing principal of Foremost Quality Logistics Inc., in Dallas. Joseph Tillman ([email protected]) is a senior researcher for Supply Chain Visions, Ltd.