Using Optimization to Improve Replenishment Transportation Efficiency

A VP of a $40 billion company explained a common problem, “We ship a product that may not be needed from our plants, which struggle to ship it, to our DCs, which struggle to receive it, at a premium cost.” He could have added, “And the next day, we may have no volume on that lane.” Another company complained, “Our replenishment shipments are only 85% full—this is a huge waste of transportation payload.” Simply put, operations get plans from their supply planning systems that are not efficient or, in some cases, executable.

Recognizing that good companies create good plans, and great companies execute, this article provides insight into how to take plans from supply planning systems that don’t consider such things as carrier cost and warehouse throughput and space constraints and convert them into easy-to-execute instructions that recognize the realities of the supply chain.

Shippers Schedule Everything Else but not Transportation

Companies schedule operations—production lines and warehouses—but ignore transportation. This lack of planning leads to inefficiencies and increased costs.

When scheduling, most companies consider the capacity in manufacturing, material handling and other operations, but they often assume that carriers’ capacity is unlimited and the price doesn’t change. This is not the case:

· When volume spikes, it’s necessary to go deep into the routing guide to find vehicles, often driving higher costs or requiring a sacrifice in quality or flexibility, and carriers may need to deadhead many miles to meet the tender. This generally comes at a price.

· When volume is down, labor sits idle, and carriers must go elsewhere to keep their trucks busy.

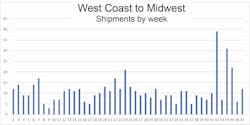

Volatility is rampant and painful, as the following example shows. How can a site or transportation manager cope with a week-to-week variation of 33 loads? (See Figure 1.)

This adds to the overall cost of operations, not to mention stress on both the shipping and receiving sites. So, any transportation schedule must also reduce volatility. It must also provide a firm order to the carrier (a tender) because most carriers don't have sophisticated systems to manage projections—they want commitments.

Including Transportation in the Overall Plan

With the aid of load-building software, the deployment plan can be translated into a transportation plan detailing the number of trucks needed on any lane for the next 30+ days.

The solution to these challenges involves optimization that smooths deployment shipments by pulling high-priority volume earlier while pushing less-needed requirements to ship later. This reduces volatility and smooths the need for trucks over the next 30 days.

The beauty of this long-range plan is that it enables securing carrier capacity (trucks) earlier. Ordinarily, when securing equipment, the shipper has predefined the contents. The earlier this happens, the higher the probability that the load is not exactly what is needed days later. But, except for rare cases, the trucking company doesn’t need to know the load contents. Thus, there is significant value in delaying determining load content to maximize the appropriateness of load contents and improve fill rates. It also allows maximizing:

· Trailer utilization—also known as load optimization.

· Shipping the most needed product

Doing all this manually is not easy or maybe even possible in today’s short planning windows. The sheer volume of data and the reliance on what happens on any day, depending on decisions made on previous days, makes for complex modeling. It’s time for mathematical optimization. The process outlined in Figure 2 shows how one Fortune 100 CPG manufacturer is leveraging optimization today.

Optimization: Key to High-Service, Low-Cost

Software that simultaneously considers all capacity, cost and operational constraints of the whole network is crucial. For example, suppose a warehouse has a space constraint. In that case, all the supplying locations need to understand and coordinate to determine which sites have the highest priority full truckloads that should ship into that location. Fortunately, existing operations research technology is very good at managing all the locations and flows simultaneously.

However, this software is not good at determining what should be on each vehicle. This is critical in the consumer products world because movements among sites are traditionally always on a full truckload basis. Thus, it's necessary to combine multiple technologies to create the mathematical optimization of what truck should ship from where and establish the priority of each load. Such software optimizes order fill, understands and respects priorities, throughput, and space constraints, and minimizes costs to determine the number of loads from each source to each destination.

Getting to the Front of the Carrier Line

These loads are tendered with a “dummy” code to reserve the trucks. The carrier has a firm order to supply a vehicle on a given day, while the shipper has multiple days to determine what should be placed on that truck. Later, much closer to the actual shipment date, an optimizing load builder, seeing the number of trucks to be filled and using the latest data, including priority, from the supply planning system, can quickly define what should be on each load. Notably, the loads must be damage-free and ensure the legality of axle loading.

Again, to execute, there is a need for a plan that works in the real world. Knowing what is on the load and understanding that it can be successfully executed, the load builder will update the information in the system of record. There is an added benefit here—using clever mathematics, the optimization successfully matches items on each load to get 5-10% more payload and requires fewer trucks over the long haul.

Focusing on ensuring that the limited number of reserved trucks have the highest-need products ensures that the most critical items are shipped first, improving order fill and enhancing customer satisfaction.

Using Optimization Improves Transportation Efficiency and Cost

The results speak for themselves:

· Transportation is now being scheduled many days into the future in such a way that the plan can economically be executed with high customer service.

· Both shipper and carrier costs are significantly reduced as first-tender acceptance rises to a much higher level. This proves that stretching the time between tender and loading enables shippers to get to the front of the queue.

· Carriers, recognizing significantly less volatility on each lane, are “encouraged” to reduce their rates to reflect the increased ease of doing business with the shipper.

· Detention is substantially reduced.

· Warehouse overtime is reduced.

· Planning staff have less stress with fewer touches.

· With load optimization saving 5-10%, fewer trucks are needed, generating a solid return on investment in both dollars and carbon savings.

In the first installation of such technology, the payback was less than three months. But that’s not all: order-fill rates and on-time customer delivery increased.

Optimizing supply chain operations requires a comprehensive approach that minimizes volatility and respects real-world network constraints. Good companies plan; great companies create an executable plan and execute plans that are both high service and work. This can only be achieved by implementing effective solutions that leverage optimization technology. By doing so, companies can significantly improve their supply chain operations, leading to cost savings, improved efficiency and increased customer satisfaction.

Tom Moore is CEO and founder of ProvisionAI, a provider of supply chain optimization solutions.

About the Author

Tom Moore

Tom Moore is CEO and founder of ProvisionAI, a provider of supply chain optimization solutions.