Forgetting is an evolutionary advantage: if the brain retained every memory and held onto every bit of information it takes in, it would be impossible for individuals to act. We need for our brains to forget information in order to make room for more relevant data as it comes along. However, while forgetting is a beneficial process, there is reason to be concerned that you do not have much control over exactly which pieces of information your brain will retain, and which ones it will allow to expire. For employers, this is a critical detail in the planning and presentation of training programs.

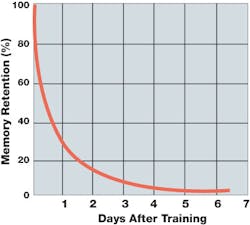

Studies that examine "the forgetting curve" have found that within a single hour of instruction, most trainees will have forgotten about 50% of what was presented. This

purging of information continues over the course of the day, as 70% of new information has been forgotten within the first 24 hours. After a week, an average of 90% of what trainees learned in their training session is gone:

This phenomenon is not a new discovery. A German psychologist, Hermann Ebbinghaus researched the processes of learning and forgetting in the 1880s and was the first to describe the forgetting curve.

Ebbinghaus noticed that information is forgotten at an exponential rate from the time learners consume it. He conducted much of his early research on himself, presenting himself with some 2,300 nonsense syllables like “NOG” and “ZAT” to ensure that the “words” were free of associations. Then, he learned lists of these nonsense syllables and took note of how many of the syllables he could recall after certain intervals of time.

From this research came the concept of the forgetting curve, describing how recently learned information was forgotten at a staggeringly rapid rate. While the rate of forgetting can be impacted by several factors, such as the subject’s difficulty, and physiological factors, like stress and sleep, the rate of forgetting across individuals differs very little. In other words, no one is exempt from forgetting.

Despite the fact that Ebbinghaus discovered all of these trends about learning and forgetting in the nineteenth century, modern manufacturing companies have been slow to adapt. Traditionally, manufacturers have approached the education of their employees with annual classroom training: long sessions dense with material that, unfortunately, is mostly going to be forgotten. With companies spending $60 billion annually on training, this rate of decline makes for an expensive but futile effort!

To make matters worse, the manufacturing sector must overcome the widening Skills Gap. As technologies and innovations continue to grow more advanced, manufacturers worldwide are looking for talent to hire. Due to the Skills Gap however, companies are finding a growing shortage of talent, leaving millions of manufacturing jobs unfilled. In fact, according to a report done by Deloitte, nearly 3.5 million manufacturing jobs will be needed in the next decade, but only 1.5 million will be filled. With potentially 2.5 million jobs going unfilled in the next decade, manufacturers cannot afford to waste time and money on ineffective training methods.

Manufacturing executives see developing their workforces as the way to remedy the Skills Gap problem, as 94% agree that internal employee training and development programs are the best workforce development strategies. However, employers must be sure to invest in effective training and development programs, ones in which employees will gain long-term knowledge essential to excelling at their jobs.

How can companies avoid poor training strategies and slow the widening skills gap? They can capitalize on some of the critical findings of Ebbinghaus’ research:

• Learning is more effective when spaced out over time than when it’s “crammed” into a single marathon study session. Provide ongoing, just-in-time learning materials where engineers and designers can search for answers to their questions and/or review concepts and functions that they use less frequently. Instead of having to interrupt other colleagues for help, engineers and designers can watch a short lesson to brush up and then immediately get back to work.

• Though the act of forgetting is an immediate and rapid process, information can be relearned. In other experiments, Ebbinghaus found that relearning was easier and took less time than the initial learning of the same material. He also discovered that it takes longer to forget information with each relearning. When given on-demand learning resources, engineers and designers can easily and quickly relearn information they may have forgotten.

In addition to providing this immediate, just-in-time support to your team, managers also can guide the learning of their team. By creating assignments, you can meter-out the information you want your team to master, and revisit it at any time.

• Give your team a place to start; assignments help your designers know where to begin.

• Provide your designers with recommendations of what lessons to watch to improve their skills the most.

• Help your team evaluate their progress and track their understanding with assignment Baseline and Review Tests.

• Provide guidance to your team to help them master more advanced functions and prepare for software certifications.Megan Davidson is the director of Customer Success for SolidProfessor, an online learning company specializing in software applications used in engineering and design.

This article was originally posted on Foundry. Foundry, like IndustryWeek, is a part of Penton's Manufacturing and Supply Chain group.