While a majority of manufacturers have implemented digital platforms, more than half (51%) lack the skills to operate these factories, according to a new study from Accenture.

Cracking the Code on the Digital Factory, a report based on a global study of 450 manufacturers, found that a growing skills gap is one of their biggest concerns – a situation that has worsened in recent years as manufacturers have transformed their operations using new technology, analytics and mobility capabilities.

Fifty-five percent of manufacturers, up from 38% in 2013, reported a skills gap among skilled trades laborers, who need to operate increasingly advanced digital machinery and equipment, such as 3D printers or modeling and simulation tools on the plant floor.

Likewise, 60% of manufacturers, up from 31% in 2013, cited a shortage of maintenance workers skilled in the use of predictive maintenance analytics that leverage data from embedded sensors in a machine-to-machine environment.

“For manufacturers to realize the full potential value of digital factories, they need to redesign their workforce to include new manufacturing skills, such as analytical reasoning and data-driven decision support,” said Russ Rasmus, managing director, Accenture Strategy. “Developing a comprehensive talent strategy inclusive of new digital skills is an imperative for today’s manufacturers.”

Digital Factory Leaders

The research identified a small group of manufacturers (8%) that outperformed their peers by increasing production and profitability by more than 10% since 2013. These “leaders” are more likely than their peers to understand which new skills they need for future growth and success, and have a more effective strategy to attract, develop and retain this new breed of manufacturing talent.

A majority of these leaders (73%) more frequently reported already having the requisite digital skills, as compared to 49% of other manufacturers, and they were nearly 50% more likely to report a higher degree of visibility into what skills they needed. That has allowed most of the leaders (81%) to achieve greater internal workforce mobility in roles involving digital, enabling them to match employees with managers who need those skills.

Barriers to Success

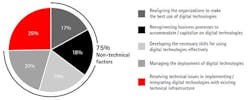

While these digital factories are enabled with rapidly developing technology innovations, the technological aspect of their implementation is not the top barrier to success. Seventy-five percent of the deployment challenges cited by survey respondents are related to skills, organizational change or structure, and the talent within the organization.

Chief obstacles that hinder manufacturers’ digital adoption

“Manufacturers must aggressively manage these non-technical barriers as they deploy their digital factory capabilities. These include the ability to create new processes, lead teams made up of workers and machines, and constantly update training programs,” said Rasmus.