Proper Machine Guarding Guards People

The downhome American adage, "If it ain't broke, don't fix it," seems like it must date back to colonial times. In fact, the phrase was popularized in the 1970s, but its widespread use makes it seem older than it really is. In that sense, the phrase is a bit like safety mats.

Introduced in the 1950s, safety mats became such a common tool in industrial machine guarding that some people seem to believe they date to the Industrial Revolution. Not quite.

A recent spate of articles is touting the death knell of safety mats in the wake of safety laser scanners. However, both machine guarding technologies have their place in today's industrial landscape. Decision-makers need a good understanding of the basic factors about each to make proper decisions regarding the type of guarding to employ for safety.

How Mats and Scanners Work

Safety mats are easy to understand. Typically, a safety mat is a simple, normally open switch that closes when weight is applied to it. Each safety mat has four wires that, when wired to a controller, provide the redundancy required to monitor the wires for opens and shorts due to mis-wiring or possible damage. Good safety mats feature heavy-duty, impact-resistant construction, with molded traction patterns to help prevent personnel from slipping.

Safety laser scanners use time-of-flight technology for distance detection. A pulsed laser beam emitted from the scanner is reflected back if it meets an object within the predefined areas. The reflected signal is registered by the scanner's receiver, which uses the time between sending and receiving the signal to calculate the distance between the scanner and the object.

Stationary versus Mobile

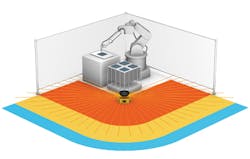

Safety mats are widely used in stationary applications, while safety laser scanners may be used in stationary or mobile applications. Safety mat devices are used to guard the area around hazardous machines. They are available in a variety of sizes and custom shapes to fit many floor layouts, especially around awkwardly shaped machines where other guarding devices are not flexible or practical to use.

When safety mats are secured to the floor by proper trims, they provide sensing across their entire surface to send a stop signal to the machine before the hazard can be reached by an individual.

Typical applications for safety mats include:

- Material handling equipment

- Welding robots

- Assembly machinery

- Packaging machinery

- Punches

- Presses

- Robot work cells

Many zone sets can be programmed into a safety laser scanner, which can then be switched from one set to another based on specific needs for a process or operation. For example, the scanner can be looking at "zone A" for the first part of the operation, "zone B" for the second part, "zone C" for the third part, and so on. This ability to dynamically change is key for mobile applications. Users can program different patterns and switch from one to another based on the immediate need.

In a mobile application such as on an automated guided vehicle (AGV), safety laser scanners enable faster and more precise navigation through the factory floor, for maximum efficiency.

Environmental Factors

Laser scanners are optical devices; they have a sensitive receiving element that requires the control of certain conditions, such as dust or smoke in the environment and ambient light. This doesn't mean that scanners can't be used in such environments; users just have to take certain precautions. They need to be mounted out of direct sunlight and in locations where there isn't excessive smoke or dust.

For example, if there is a skylight in the ceiling of the work area, a scanner cannot be positioned to look up directly into the skylight because it could be "blinded" by direct light at high noon.

Consider a scenario from the automotive industry: A Tier One supplier to a major automaker presses and cuts fabrics for car interiors. During the manufacturing process a lot of lint and fiber is generated. Personnel on the plant floor are compensated in part on a per-piece basis, so operators literally run up and down a heat press as they aim to make as many parts as possible. As they move, they stir up dust and fiber, causing the laser safety scanners to see fibers flying for 10- to 20-second increments. So instead of producing more parts, fewer are being manufactured because scanners shut down the press until the fibers settle.

In this application and others like it, safety mats could be a viable alternative to safety laser scanners.

Lifecycle and Costs

Safety mats are largely impervious to outside factors affecting their performance. However, if they are used in an environment where lift trucks are repeatedly driven over them, this traffic may reduce their effective life. Additionally, exposure to organic or chlorinated solvents may also compromise their integrity and performance.

For safety scanners, shock and vibration are probably the major threats to their performance. Also, some fluids or lubricants may penetrate their seals. Physical impact is also a risk, so it is recommended to mount scanners away from operators or other floor traffic.

Historically, safety mats were about a quarter of the cost of safety laser scanners; but that cost differential has closed by half over the last decade.

Today, cost of ownership factors tend to favor scanners in large area applications, while in small area applications safety mats tend to be more cost effective. Installation takes longer with safety mats because they are physically anchored to the plant floor, but installation and troubleshooting for safety mats are considerably simpler than with safety laser scanners.

Another issue is the manufacturing process and site configuration. Many factories have flexible work cells that can be picked up and rearranged, so they are easily reconfigured as processes are adjusted or refined. If those cells have safety mats they need to be uninstalled and reinstalled at the new cell location—a time-consuming and laborious process. So for any installation where equipment is moved periodically, safety mats are not likely to be recommended.

In the end, both of these machine-guarding technologies are viable options for manufacturers. Their application should depend on how their merits meet the objective conditions of the manufacturing environment in which they are applied.

Sergio Aguilar is product manager and Trang Nguyen is product specialist for Omron Automation and Safety.