Let’s talk about the Super Bowl. But first, let’s talk about sales and operations planning (S&OP).

To optimize their financial, customer service and sustainability goals, companies need an S&OP process that is strategic, visionary and long-term in nature—working seamlessly alongside a short-term, tactically focused sales and operations execution (S&OE) process that carries out the plan. While these activities should be distinct from one another—two separate halves of a closed planning-and-execution loop—too often they are muddled together.

In high-level S&OP meetings, valuable time is wasted discussing day-to-day tactical problems, instead of the bigger picture, including market trends, the profit-and-loss statement, the balance sheet, competition, demand realization, and capacity expansion scenarios.

The Solution? Optimizing Both Planning and Execution

A closed-loop S&O planning and execution process demands two distinct teams with different objectives, goals, agendas and meeting cadence. S&OP is purely strategic in nature, with the goal of meeting the budget, as well as taking a visionary look at major threats and opportunities. It’s informed by data gathered across a shared technology platform that aggregates and analyzes information on industry trends, product launches, competitor advances, long-term demand forecasts and other factors that may signal risks and opportunities.

Daily execution issues are not part of the long-term S&OP meeting. These planners take a high-level perspective on where the business is heading over the next one to two years. These plans are then handed off to a dedicated S&OE team, which meets at a much more frequent cadence to look at short-term issues such as materials shortages, capacity issues, anticipated staff overtime, transportation availability and the associated financial impact. In identifying and addressing these issues, the S&OE team relies on the same, shared technology platform as the S&OP team so that there is no distortion between the long-term S&OP decisions and the short-term tactical planning S&OE.

Machine learning (ML) and artificial intelligence (AI) can help by automating decisions in the short term and feed into the longer-term S&OP process. For example, smart technology can compute real-time, dynamic parameters, like lead times from the short-term S&OE process, and leverage them for the longer-term S&OP process, as opposed to relying on static planning parameters. This feedback loop will make the entire S&OP-S&OE process smarter and more agile on an ongoing basis.

Strategic Planning and Smart Execution: A Playbook for Success

To witness a successful closed-loop planning-and-execution process firsthand, just tune into Super Bowl LIV taking place this Sunday.

During the off season, the general manager and coaches refine the team roster playbook—a collection of plays prepared to address the challenges the team is likely to face in the coming months. The coaching staff reviews performance statistics and watches competitors’ films from the previous season to prepare for what they’re going to be up against this year—analogous to S&OP.

But it’s up to the coaches and players to execute that week’s game plan successfully—which means real-time agility and problem-solving. When actual performance during a game deviates from the long-term plan, smart, seasoned coaches and players make in-game adjustments to keep the plan on track, i.e., S&OE. The entire team deals with short-term obstacles and learns from the results. Post-game, the coaches and players work together to strategically adjust the long-term plan and improve the playbook before the next game.

Watching a football game unfold, it’s easy to see the logic behind this closed planning-and-execution loop. And it mirrors the way many successful sports teams work in the real world, season after season.

The Payoff Is Significant

Companies like Lenzing, supplier of specialty textile fibers for the fashion industry, are investing in new technologies to synchronize supply, demand, capacity and financials and optimize both profits and sustainability.

“We facilitate a closed loop S&OP and S&OE process that allows us to evaluate rapid trade-offs between the different demand/supply/financial scenarios and show us the delta to the original plans,” notes Simeon Nachev, value chain manager for Lenzing. “These rapid what-if simulations help us see the impact on operational and financial plans, ensuring the entire organization can react to changing market conditions with agility and reconcile easily our strategic and tactical plans. Also, now our mid- to long-term S&OP decisions roll in seamlessly into the tactical short-term S&OE horizon and vice versa, leading to a connected, synchronized, closed-loop S&OP and S&OE process. By doing that, we are now more responsive and able to produce what the market needs, which of course leads to lower inventories, higher stock turns, greater customer service and decreased missed sales opportunities.”

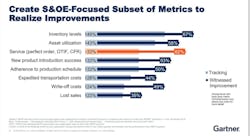

Gartner has published the results of an internal study on companies who have implemented a distinct S&OE process (see chart).

Of those companies that focused on reducing inventory levels via S&OE, 67% saw an improvement. Sixty-two percent of enterprises chasing service improvements made real progress. Other measurable benefits of an S&OE initiative included greater asset utilization, higher success rates for new products, better adherence to production schedules, lower expediting costs for transportation, reduced write-offs and fewer lost sales.

Not only did these companies achieve short-term benefits, but these benefits had huge potential strategic implications over the longer term. For example, by achieving more successful product launches, these organizations could communicate the key success factors across the entire supply chain, from product development to marketing, to make future launches even more likely to succeed.

Technology has come a long way, and best-in-class companies are investing in solutions that seamlessly orchestrate their S&OP and S&OE processes. In addition, new innovations, like AI and ML, further support the closed-loop process by gathering and applying critical data. As execution issues are successfully managed, ML can identify and record the earliest signals of these issues, so these disruptions can be recognized earlier in the future.

Just like seasoned NFL coaches and players work together to strategically adjust and improve the playbook before the next game, or for the next season, companies can measure and record the success of the intervention, creating a repository of best practices, using the data to become smarter and more autonomous over time. As the system learns, eventually a much lower level of human intervention may be required for common execution issues, allowing supply chain talent to focus on more strategic opportunities.

Salim Shaikh is senior director of global industry strategy at JDA Software (www.jda.com), a provider of supply chain solutions.