How to Avoid Forklift Injuries

National Forklift Safety Day, which occurs on the second Tuesday of June, is an opportunity for companies to focus on this aspect of safety. Annually, between 35,000 and 62,000 injuries every year involve forklifts, according to the Industrial Truck Association, which created this event, with media support at launch from MH&L

OSHA has estimated that over 70% of forklift accidents were preventable, and the safety agency has long advocated for safety equipment and more diligent training.

With approximately 4.5 million forklift operators in the U.S. workforce, one of the largest manufacturers of forklifts, Toyota Material Handling North America, has taken an active role in the issue and emphasizes the need to foster a culture of safety as a cornerstone of operational success.

“At Toyota, we understand that a lasting culture of safety is built on sharing knowledge and best practices, which we call yokoten,” said Bret Bruin, vice president of Toyota Sales for Toyota Material Handling North America, in a statement. “Operator training supports our shared responsibility to protect lives and prevent incidents.”

Keeping Safety Top of Mind

“National Forklift Safety Day is a great reminder that safety starts with training, technology and a culture of accountability,” says Andre Marshall, product manager of Bobcat, another forklift manufacturer. The company offers five key practices to keep forklift safety top of mind:

1. Train and Certify Every Operator

Safety begins with proper education. OSHA mandates that all forklift operators complete a two-phase training process—including classroom instruction and hands-on evaluation. Employers should tailor training to the specific types of forklifts and environments their teams work in, as well as leverage the machine’s operation and maintenance manuals for model-specific instructions.

2. Conduct Daily Inspections and Preventive Maintenance

OSHA requires that forklifts be inspected at the start of every shift. Daily walkarounds should include checks for leaks, tire wear, fluid levels and fork condition. Operators should also test brakes, lights, horns and alarms. If an issue is found, it’s important to tag it out of service until it can be repaired. A well-maintained machine is a component of safe operation, and routine inspections help mitigate potential issues.

3. Be Aware of Your Environment

Whether on a warehouse floor or navigating outdoor terrain, situational awareness is key. Operators must stay alert to pedestrians, floor conditions, ramps, blind spots and other vehicles. Using alarms, mirrors and safety lights can help enhance visibility and communication between team members.

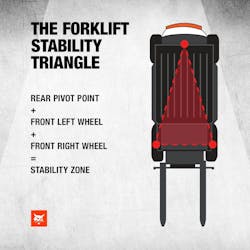

4. Understand Load Capacity and the Stability Triangle

Among the leading causes of forklift accidents are tip-overs, of which overloading can be a contributing factor. Operators must know how to read the data plate and understand how factors like lift height, load length and attachments affect capacity.

Ensuring the load’s center of gravity stays within the forklift’s Stability Triangle (see image below) is crucial for safe operation. This triangle is formed by connecting the two front wheels and the pivot point of the rear axle. With a load, the center of gravity of the forklift is towards the center of the triangle. But as you add more weight to the forks or raise the mast with a load, the center of gravity shifts to the front of the triangle. Moving the center of gravity out of the Stability Triangle by adding too much weight or adding weight in the wrong places can cause tip-overs.

5. Embrace Technology and Safety Features

Many forklifts today include advanced safety features designed to protect both operators and bystanders, such as stability systems and collision warning systems. Additional features—including high-visibility cabs, rear grab bars with horn buttons, and optional blue safety lights—can improve operator and bystander awareness.

Causes of Forklift Injuries

OSHA lists the following as top causes of forklift accidents:

#1: Forklift Rollovers or Tip-overs

Forklifts are prone to rolling or tipping over, and this is a particularly dangerous type of accident. It’s estimated that 24% of all forklift accidents are turnovers, but they account for 42% of all recorded injuries. In other words, if you’re in a forklift rollover accident, you’re more likely to get seriously injured.

The most common causes of rollover or tip-over accidents involve dangerous speeds, abrupt movements, and poorly balanced loads.

To prevent forklift rollover accidents:

- Take corners slowly. Turning a forklift shifts the center of gravity, which increases the risk of a rollover, especially if you’re moving too fast. Remember: slow is smooth, and smooth is safe.

- Don’t exceed your load capacity. Maximum load capacities are printed on the data tag. Overloading your forklift can result in a tip-over.

- Understand load balance. Proper load balance is also critical to maintaining a stable center of gravity, so you need to avoid lopsided loads. Weight should be centered. Additionally, you should only drive when the forks are lowered – operating with an elevated load creates a dangerous imbalance.

- Only operate on smooth, even surfaces. Uneven surfaces can cause sudden shifts in the center of gravity, resulting in tip-overs.

#2: Pedestrian Collisions

Forklift accidents involving pedestrians are another particularly dangerous type of accident, causing a disproportionate amount of serious injuries. Roughly 20% of forklift accidents involve a pedestrian, but 36% of forklift-related deaths do.

Pedestrian collisions include several different types of accidents in which a forklift:

- Crushes a pedestrian against a stationary object (25% of all recorded forklift injuries)

- Strikes or runs over a pedestrian (11%)

- Crushes a pedestrian between two vehicles (11%)

- Falls onto a pedestrian or strikes them as it falls (8%)

To prevent forklift-pedestrian accidents:

- Avoid approaching someone standing in front of a stationary object. Pinning or crushing accidents are very common, which is why OSHA forbids driving up to a pedestrian standing against a bench, wall, pallet stack, or other immovable object.

- Use physical or symbolic pedestrian barriers. By installing physical barriers or laying down floor tape, you can alert pedestrians to areas where they’re at risk of a forklift collision.

- Use warning lights and alarms. Installing flashing lights on forklifts can alert pedestrians to potential danger. Backup alarms are particularly important since drivers have reduced visibility.

- Install wall-mounted mirrors. Eliminate blind spots for forklift operators with mirrors that help them see around corners and other obstructions.

- Follow speed limits. Driving too fast gives both the driver and the pedestrian less reaction time to avoid a collision.

- Avoid distracted driving. Driver inattention is a huge factor in pedestrian collisions. Take breaks if you feel fatigued, keep your mind on your work, and be aware of your surroundings.

#3: Falling Loads

When inventory falls from the forks of a truck, both operators and pedestrians are at risk of injury.

To prevent falling load accidents:

- Secure loads of loose items carefully.

- Center all forklift loads.

- Use a load backrest to prevent items from falling into the operator compartment.

- Do not operate a forklift with bent or damaged forks.

- Avoid moving, lifting, or tilting the mast too abruptly or quickly.

#4: Personnel Falling From Forks

Forklifts are not designed to lift people, but some people “ride the forks” anyway out of a desire for convenience or efficiency. The problem is that you’re likely to fall, resulting in serious injuries.

Never ride the forks of a forklift. People only belong in the operator’s compartment. Aerial lifts are designed for safely lifting personnel to height, and a forklift is a dangerous alternative.

#5: Emissions Poisoning

It can be dangerous to operate a forklift (particularly those with combustion engines) in an enclosed space because toxic fumes can build up and make operators and other personnel sick. Forklifts with lead-acid batteries don’t produce emissions during operations, but they can emit hazardous fumes when charging.

To prevent emissions poisoning from a forklift:

- Use lithium-ion forklifts for indoor applications and enclosed spaces.

- Charge lead-acid battery forklifts in a well-ventilated space.

- Avoid excessive idling when operating a combustion forklift in an enclosed space.

- Use carbon monoxide monitors when operating a combustion forklift in an enclosed space.

- Maintain forklifts regularly.