On March 26, 2012, the Occupational Safety and Health Administration’s (OSHA’s) revised Hazard Communication Standard (HCS) 29CFR 1910.1200, which adopts the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), went into effect, under the name HazCom 2012. This rule impacts every workplace in the United States subject to OSHA regulation. Under HazCom 2012, some key dates of compliance—most of which have passed or conclude at the end of 2015—include:

If there is pertinent physical and chemical data missing from your GHS format SDS or training has not been provided to employees on the new HCS standard, then employers should find a reputable company to provide testing to fill in SDS missing physical and chemical properties, and also train their employees on the HCS 29CFR 1910.1200 standard and its requirements.

This article reviews the major changes that have occurred to the HCS, with special emphasis on requirements for manufacturers, importers and distributors.

Understanding the Origins of GHS

The GHS was driven in response to problems generated from multiple, inconsistent chemical classification and labeling systems internationally. In 1992, a United Nations mandate prompted an agenda to develop a worldwide, globally harmonized system for the classification and labeling of chemicals, with the primary objective of increasing the quality and consistency of information provided to workers, employers and chemical users. The mandate, which took a decade to negotiate, was finally adopted in 2003 and published in what is commonly known as the “Purple Book,” which is in its 3rd revision. The United States was an active participant in the development of the GHS and is a member of the UN bodies established to maintain and coordinate implementation of the system.

It is currently a voluntary international identification system containing a set of recommendations or collection of international best practices that does not impose an obligation to comply to all or even any of the GHS. It must be adopted by a country and integrated into existing governing laws/regulations before it can become law in that country. Countries can pick and choose which parts of GHS (called the building-block approach) they wish to incorporate.

In May 2005, OSHA added GHS to its regulatory rulemaking agenda and published an advance notice of proposed rulemaking (ANPR) on September 12, 2006. A significant milestone was achieved when revisions that align HCS with GHS were published on September 30, 2009.

Other Federal Agencies are also impacted by GHS and have initiated their own integration efforts in concert with OSHA, including:

• Environmental Protection Agency (EPA), Globally Harmonized System for Classification and Labeling of Chemicals;

• US Department of Transportation (DOT), Global Harmonization of Hazard Classification and Labeling Systems; and

• Consumer Product Safety Commission (CPSC), Policy of the U.S. Consumer Product Safety Commission on the Globally Harmonized System of Classification and Labeling of Chemicals.

As of August 2015, over 65 countries have adopted or made some progress toward implementing or adopting the GHS. Some of the related regulations in other countries which impact certain U.S. companies include:

• Health Canada, Globally Harmonized System of Classification and Labeling of Chemicals;

• Mexico GHS, Harmonized System of Classification and Hazard Communication of Chemicals;

• NMX-R-019-SCFI-2011 is known as the Sistema Armonizado de Clasificación y Comunicación de Peligros de los Productos Químicos. Published in the Official Gazette of the Federation on June 3, 2011;

• European Commission, Classification, Labeling & Packaging (CLP) of Substances and Mixtures Regulation No. 1272, published December 31, 2008;

• European Commission, Registration, Evaluation, Authorization and Restriction of Chemicals (REACh) 1907, which became effective on June 01, 2007;

• China New Chemical Substance Notification, commonly referred to as China REACh;

• Switzerland GHS, partial revision to chemical regulation approved by Federal Council, November 10, 2010; and

• Turkey REACh, Turkish Ministry of Environment & Forestry (MOEF) inventory and reporting requirements.

Major Changes to the HCS

OSHA expects the changes to the HCS to enhance worker comprehension, resulting in more appropriate handling and use of chemicals. The harmonized format of the safety data sheets will enable workers to access the information more efficiently.

Currently, multiple labels and safety data sheets for the same product often must be developed when shipping to different countries. This creates a major compliance burden for chemical manufacturers and those involved in international trade, increasing the cost of providing the required hazard information. The adoption of the GHS will minimize this burden.

The proposed changes include:

Hazard Classification: The proposed rule provides specific criteria for the classification of health and physical hazards, as well as the classification of mixtures.

Labels: Chemical manufacturers and importers will be required to provide a label that includes a harmonized signal word, pictogram and hazard statement for each hazard class and category. Precautionary statements must also be provided.

Safety Data Sheets (SDS): Will be required to have a specified 16-section format:

1. Identification

2. Hazard(s) identification

3. Composition/information on ingredients

4. First-aid measures

5. Fire-fighting measures

6. Accidental release measures

7. Handling and storage

8. Exposure controls/personal protection

9. Physical and chemical properties

10. Stability and reactivity

11. Toxicological information

12. Ecological information

13. Disposal considerations

14. Transport information

15. Regulatory information

16. Other information, including date of preparation or last revision.

It should be noted here in the SDS section that although not required on the labels themselves by GHS, the HCS requires “unclassified hazards” such as pyrophoric gases, simple asphyxiants and combustible dust—now termed “hazards not otherwise classified” (HNOC)—to be disclosed in section 2 of the SDS. Combustible dust has its own Combustible Dust National Emphasis Program Directive CPL 03-00-008 and also consensus standards and guidelines from the National Fire Protection Association, NFPA.

Information and Training: The GHS does not address training; however, the HCS requires that workers are trained on the final rule to facilitate recognition and understanding of the new labels and safety data sheets.

Major Changes

The following is a summary, by section, of major changes.

Definitions

This paragraph defines many of the terms used in the proposed HCS. OSHA has changed a number of the definitions, as well as the actual terms used, to be consistent with the GHS by adding the following definitions:

Classification, Hazard category, Hazard class, Hazard statement, Label elements, Pictogram, Precautionary statement, Product identifier, Safety data sheet, Signal word, Substance, and Unclassified hazard.

The following definitions were deleted:

Combustible liquid, Compressed gas, Explosive, Flammable, Flashpoint, Hazard warning, Identity, Material safety data sheet, Organic peroxide, Oxidizer, Pyrophoric, Unstable (reactive), and Water-reactive.

The following definitions were revised:

Chemical, Chemical name, Hazardous chemical, Health hazard, Label, Mixture, and Physical hazard.

Hazard Classification

Employer obligations under the HCS are distinct from those of manufacturers, importers and distributors. The “responsible party” named on the SDS and label would be held accountable for the accuracy of information provided and potentially subject to citation if a violation of the HCS was determined to exist according to Hazard Communication Directive, CPL 02-02-038, paragraph (E)(1)(d)(1). The GHS has specific criteria for each health and physical hazard, along with detailed instructions for hazard evaluation and determinations as to whether mixtures of the substance are covered.

OSHA has included the general provisions for hazard classification in paragraph (d) of the revised rule, and added extensive appendices that address the criteria for each health or physical effect. Mandatory Appendices A and B provide classification guidance for Health Hazards and Physical Hazards, respectively. The hazard classification criteria contained in the HCS allows the use of existing credible data instead of requiring additional testing. Thus a weight-of-evidence approach to the classification of substances can be used. However, in the absence of reliable data, testing may be required.

The person classifying a chemical or substance should use accredited laboratories where possible, maintain records on the level of substance constituents when used as a basis for classification, ensure that studies are of a consistent and reliable quality, and have access to documentation that provides theoretical rationales if applied.

Hazard Communication Program

The GHS does not have provisions regarding hazard communication programs, and thus this paragraph is essentially the same as in the current HCS. No substantive (only terminology) changes have been made in this paragraph of the revised HCS.

Labels

Under this paragraph, chemical manufacturers and importers must provide a label that includes: a product identifier that matches the SDS, a pictogram (black hazard symbol on white background with red diamond border), a harmonized signal word (“danger” or “warning” as described by severity) and hazard statement for each hazard class and category. In addition, precautionary statements must also be provided, as well as supplier information.

A new mandatory Appendix C indicates what specific information is to be provided for each hazard class and category once a chemical is classified. These proposed requirements are significantly different from the existing HCS, which allows chemical manufacturers to use whatever language they believe is appropriate to convey hazards. The existing HCS does not require the use of pictograms, specific signal words, or precautionary statements.

The proposal’s approach will both improve communication aspects of the label, and facilitate compliance by providing the specific information to be included based on the hazard classification.

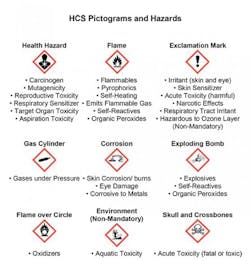

The GHS uses nine pictograms to convey the health, physical, and environmental hazards. The proposed HCS requires eight of these pictograms, the exception being the environmental pictogram, since environmental hazards are not within OSHA’s jurisdiction. All nine GHS HCS pictograms are shown in the picture below:

Safety Data Sheets

Paragraph (g) indicates the headings of information to be included on the safety data sheet and the order in which they are to be provided. This is supplemented by a mandatory Appendix D(22), which indicates what information is to be included under each heading. This format is the same as the ANSI standard on safety data sheets, which is already familiar to U.S. employers.

Training and Information

The provisions in paragraph (h) have been clarified to indicate that the new label and data sheet formats and presentation of information must be discussed in training. All employers will be required to conduct additional training to ensure that their employees are familiar with the standardized labels and safety data sheets. Otherwise, the training provisions remain the same as the existing HCS.

Trade Secrets

The trade secret provisions in paragraph (i) of the GHS are consistent with the previous HCS of 1994 with the exception that the GHS, unlike the current HCS, requires disclosure of the percentage composition of mixtures on the SDS. The HCS of 2012 adopts this requirement, but allows the manufacturer to claim trade secret protection for this requirement. This is the only substantive change to the existing standard’s trade secret protections.

OSHA anticipates the HCS of 2012 standard will prevent 43 fatalities and 585 injuries annually, with a net annualized savings of approximately $500 million a year. However, in light of a few recent “near miss” and “incident” investigations I have been on and the recent warehouse explosion incidents in Conroe, TX, and in Tianjin, China, there appears to be a lot more that employers can do to enhance their and their employees’ knowledge, properties and hazards of the chemicals they handle, process, package, store and ship.

A good SDS for a chemical should contain the required 16 sections per the GHS system stated above and should be complete without missing or incomplete information. It should provide the necessary information for training personnel on what the chemical is, its chemical composition, its hazards, physical and chemical properties—especially flash, melting and/or boiling points, first aid and fire-fighting measures, handling and storage considerations, and necessary personal protection and exposure control necessary to handle and store the chemical within the facility.

Walter S. Kessler is senior process safety specialist with Chilworth Technology, a one-stop source for industry’s process safety and optimization needs