Why Lean Supply Chains are Strongest

With daily news of earthquakes, tornadoes, tainted ingredients, economic meltdowns of companies and countries, global uprisings, and the like, many companies have come to realize how little they know about their own supply chains.

In the effort to meet customer requirements in this environment, companies have inadvertently transformed their supply chains into convoluted networks that must first be unwound and understood before efforts toward simplification and increasing resilience can be taken.

Many supply chains today are quite complex, spanning multiple countries and organizations, and are in constant flux. The need for lower costs has driven many companies to adopt global sourcing strategies that may not fully consider all impacts. Some prevailing issues in these complex supply chains include:

Lack of visibility/clarity across the end-to-end supply chain

Low cost country (LCC) sourcing strategies have made it increasingly harder for companies to know their suppliers and even more difficult to know their suppliers’ suppliers. This complexity breeds a lack of control and increases errors, and may put a company at higher levels of risk than they are willing to tolerate.

Difficulty understanding total costs

While manufacturing costs may be less in seemingly cheaper countries, it is necessary to evaluate the total cost of delivery, including tax implications, customs and trade management considerations, transfer pricing implications, distribution costs, and the impact of supply disruptions due to “unforeseen circumstances.”

Vulnerability from single-source suppliers

Typical IT organizations have disaster recovery plans to ensure that systems and data are protected from disruptions. Similarly, a supply chain should be resilient enough to continue producing should there be a disaster in one location. Relying solely on one source could yield crippling effects to a company and product manufacturing.

Inelasticity of the supply chain to meet unexpected demand

Many companies have found the lack of transparency, extended lead times, and increased levels of inventory required to support complexity have significantly reduced their ability and flexibility to respond to changes in customer demands and requirements. Supply chain flexibility is key to a scalable and sustainable operation.

The Means to be Lean

In the past decade, many companies have experienced financial and consumer backlash due to the complexity of their global supply chains. As a result, many companies have taken steps toward “on-shoring” and leaning-out their supply chains.

Lean means considering the efficient movement of a product to the customer while also continually improving operations by eliminating wasteful activities (i.e., those that do not provide value to the customer).

The benefits of Lean principles include increased productivity, improved customer satisfaction, improved quality, and enhanced supplier relationships. A Lean supply chain enables a better understanding of the components, dependencies, and risks which enable improved management of customer demand and brings decreased lead time, inventory, and costs.

While lean principles can be used to improve any process, the most effective approach is an enterprise-wide, transformational lean journey. Critical requirements to starting this journey include:

• Realizing that all steps in an organization are inherently tied to the customer; and

• Understanding that in the constantly changing environment, there is always room for improvement.

To begin the lean journey within the supply chain, managers should first and foremost assess their current state. That is, understand what the current environment is, how the processes are linked, and what are the pain points for the customer or areas of risk for the company.

It is important to note that the supply chain is not just the movement of products, but rather is the linkage of steps required to produce value for the customer. Key decisions must consider the total cost impacts, resiliency of the supply chain, and opportunities to improve overall customer and shareholder value.

Once the current state has been assessed, the company should take ownership for managing their end-to-end supply chains. This has become increasingly difficult as supply chains cross regions and organizational boundaries. Organizations need to stop passively looking at their supply chain and proactively examine, manage and mitigate risk. This is critical not only to save costs but to achieve the ultimate purpose of improving value to the customer.

Proactive management includes:

• aligning supply chain strategies to customer value,

• setting value metrics,

• creating a corporate dashboard,

• establishing monitoring tools to identify areas of risk, and

• taking early corrective action to mitigate the risk of broader, wider supply chain disruptions.

Challenge Complacency

While cost will continue to be a major driving force for change, we must challenge the complacency of today’s managers and thought processes. Leadership must question current assumptions and prepare themselves for potentially revolutionary changes in their supply chains.

The fundamental mantra of a lean supply chain is continuous improvement and evolution to the next best state. Thus, complacency is inherently impossible when operating in a true lean environment.

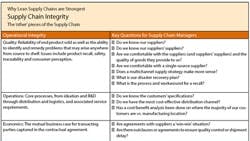

Managers must evaluate their current supply chains in light of their overall supply chain integrity, which encompasses not only the operational view but the reputational aspect as well. The total cost impacts experienced from supply chain disruptions must be quantified.

Evaluating the supply chain holistically, understanding each link in the chain, and aligning to meet customer requirements are critical to mitigating risk, reducing long-term costs and enabling growth.

Lean’s connected thinking and intolerance for waste can produce tangible bottom-line benefits and bring a shift in the mindsets and behaviors of the organization to eliminate waste and complacency while driving growth.

Brian Bilsback is a director and Dasha Maximov is a consultant at PricewaterhouseCoopers LLC.