MIVOR, Europe's biggest apple growing cooperative, is made up of 400 member farmers, with 2,700 acres of orchards, producing over 500 million apples annually (100,000 tons). Fifty percent of the total harvest is distributed throughout Italy, with the remaining 50% is exported to 49 countries throughout Europe, North Africa and Asia.

When MIVOR was formed in 2007, its total apple production was 60,000 tons annually. Since then, the cooperative has expanded its output by nearly 70. This tremendous increase in apple production has necessitated the implementation of more advanced systems for streamlining post-harvest apple sorting, storage and distribution.

Apple production in northern Italy follows a seasonal cycle, with the apple harvest taking place in September. In the orchards the apples are loaded into lined buckets inside of large bins. These apple-filled bins are picked up by forklifts, loaded onto trucks and transported to MIVOR's sorting, warehousing and distribution facility in the municipality of Latsch. Over 300,000 bins with apples are transported to the MIVOR facility each year.

MIVOR's annual apple yield has been sorted with automation for some time. This sorting system was workable when processing half of the current apple volume. But as MIVOR's annual yield approached 500 million apples annually, an upgrade to the automated system became necessary.

MIVOR partnered with Greefa to design and implement a highly-automated sorting system that would sort apples swiftly, accurately and gently. The new system classifies up to 65 apples per second on the basis of 3D modeling, which assesses apple characteristics out of 60 pictures for each single apple.

The apples are sorted by size, color and quality. Those apples that are bruised or cut, or have insect or disease problems, are immediately removed. The apple sorting system has a sorting capacity of 25 to 30 tons per hour depending on the apple variety.

Once the apples are sorted, they are filled back into bins, then routed via specially-designed transfer cars onto a conveyor system where the apples are delivered into MIVOR's newly-constructed refrigerated warehouse.

High-Density, High-Bay Refrigerated Warehouse

Like most large-scale apple producers, MIVOR cannot use the whole harvest it receives, at any given time. As a buffer between MIVOR's sorting system and its packaging operation, the cooperative's refrigerated warehouse comes into play.

But increasing production led to capacity constraints with bulk bins and storage space in its existing refrigerated warehouse. The result was damage to the product, and accidents with forklift traffic which led to production downtime. It became apparent that the cooperative's warehouse was no longer adequate.

"One advantage that apples have over other more perishable fruit crops is that they may be successfully kept in storage for a few weeks to several months, providing storage conditions are ideally maintained for specific apple varieties," explains Martin Pinzger, CEO of MIVOR. "This, however, requires precision environmental control, and precise product tracking and movement throughout the warehouse facility, something our operation did not have. Hence, we began looking for a better solution."

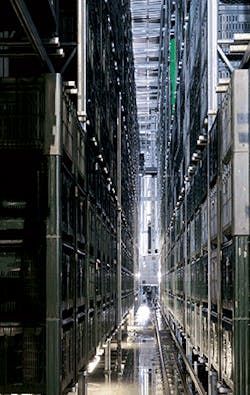

The warehouse needed to be built in the middle of a densely developed area of Latsch, so footprint consolidation was a critical factor. LTW Intralogistics was selected to engineer and build a solution, which came in the form of a 21,600 sq.ft. high-bay refrigerated warehouse, with an 88-foot-high storage capability to handle 18,600 apple bins.

At MIVOR, apples are stored in a controlled atmosphere temperature range of 34° F. Advances in controlled atmosphere technology have had a dramatic effect on apple storage logistics and opened up markets hitherto unavailable for fresh and processed apple products.

Optimizing the Load Handling Process

The MIVOR warehouse incorporates the latest automated storage and retrieval system (AS/RS) technology for automatically depositing, storing and retrieving bins or pallets from defined storage locations. Central to the MIVOR AS/RS is the usage of six stacker cranes, which permits bin inventory to be moved quickly, safely and precisely within the high-bay warehouse environment.

Stacker cranes offer reliability and accuracy that exceed the capabilities of forklift trucks. Such trucks transport product in only one direction, then return with an empty load. Stacker cranes place their load into a rack position, and then retrieve a load from storage on their way back out, optimizing the crane's movements.

"MIVOR's cranes operate within a set of top and bottom rails, which stabilize the crane, allowing greater load capacities, as well as higher rack heights," explains Christoph Leopold, head of project management and mechatronics at LTW. "It is this capability of the stacker crane that makes possible high-bay, refrigerated storage."

One major benefit for a warehouse switching from manual forklift trucks to an automated refrigerated facility utilizing stacker cranes, Leopold notes, is exemplified in maximized building volume and increased cost efficiency through high-bay accessibility. High-speed PLCs with integrated controls architecture monitor the movements of the cranes in coordination with the warehouse management system via Ethernet. The WMS's integrated controls architecture coordinates with other automated equipment in the warehouse, creating one single, efficient transport system that provides optimum throughput under any system capacity.

Built into the high-bay structure is a secondary ambient-temperature 4,000 sq.ft. warehouse for the storage and transfer of empty bins. This high-bay structure is 52 feet high and is capable of storing 1,652 empty bins, accessible via a single crane AS/RS. These bins are transferred via conveyors and lifts to sorting, and to and from packaging, eliminating the need for fork lift manual transport.

Automated Apple Dumping

Leaving the high-bay warehouse for packaging, where more than 100 employees accomplish ultra-short delivery periods, the apple bins are forklifted to an area for automated dumping of the apples into a pre-packaging water stream. Although MIVOR had been using automated dumping for some time, it required a significant upgrade to better control bin dumping, reduce product damage and improve throughput.

In 2014 LTW Intralogistics engineered a streamlined automated solution for dumping the apple bins, which is capable of controlled emptying and partial-emptying of the apple bins into the water stream; exact separation of the fruit with each order change; and integrated goods identification for every crate/order.

In this process a stack of apple-filled crates is placed on an infeed conveyor using a forklift. The number of crates in each stack is identified, the top crate of the stack is automatically grabbed by a gripper, then identified and emptied or partly emptied into the water stream without damaging the goods. After the emptying process, the empty crates are automatically stacked on an adjacent conveyor, taken over by a transfer car, and transported to a forklift removal location for empty crates, or the crates are transferred automatically back into the empty-crate warehouse.

The dumper is equipped with a camera, which identifies every crate before emptying, while informing the facility's production planning system to ensure the tracking of apples from each crate. MIVOR's fruit dumper can process up to 40 bins per hour. LTW installed 16 fully-automated fruit dumpers in the pre-zone of the packaging area.

Benefits of Automation

MIVOR's automated warehouse provides significant benefits for the cooperative's operations. It delivers rapid throughput at near 100% accuracy levels. It permits efficient bin handling and product rotation on a first-in/first-out basis, which better manages product freshness and it helps support the needs of MIVOR's marketplace. It reduces warehouse labor, improves accuracy in inventory and order fulfillment, lessens product and facility damage from fork lift usage, and streamlines energy usage.

Because of the warehouse's highly-automated computer-controlled AS/RS and WMS, the facility is capable of monitoring batch numbers, processing dates and weight as the apples and bins are moved through and stored in the facility. This level of analytics allows the MIVOR warehouse to maintain precise control on its apple products through every stage of their handling—from receiving, to sorting, storage, and through packaging and shipping.

"We have full process and product security, with traceability of every apple back to the orchard." Pinzger observes. "Throughput delays are at all-time low. And we are seeing a 33% energy savings.

Jamie Alexander writes on advancements in food processing.