Six Steps to Overcoming Capacity Shortages

Every company that depends on shipping products quickly and cost-effectively—from retailers and consumer products companies to industrial manufacturers—is challenged by the current shortage of transportation capacity. The recent economic downturn forced many businesses to make tough decisions about their unused fleets and other transportation assets, in order to remain as lean and profitable as possible.

As a result, today we are in the midst of a serious capacity shortage. As the economy picks up speed and customer confidence grows, retailers and manufacturers are eager to get their products into receiving docks and store aisles quickly—but too often they find themselves unable to accomplish this profitably. Many shippers are faced with a difficult choice: either pay a premium for alternative carriers or miss a critical sales opportunity.

Of course, transportation capacity is not a one-time problem, but an ongoing business challenge that requires shippers to successfully manage a series of unexpected ups and downs. Whether this variability is caused by an economic recession or an end-of-quarter sales surge, the business of shipping products is always going to be characterized by uncertainty. While many retailers and manufacturers are scrambling to meet current shipping challenges, they actually need to take a longer-term view and create a flexible transportation strategy that addresses the inevitable variations in both customer demand and carrier availability.

Shifting From a Tactical to a Strategic View

The cyclical nature of transportation demand requires that shippers make a significant, foundational shift in their approach. It is not enough to take a short-term tactical view, asking “How can we manage the capacity shortage over the next two or three quarters?” Instead, executives need to take a longer-term, strategic view that enables them to manage both excess capacity and transportation shortages over a two- or three-year period.

This represents a major change for any business, but it is the only way to prepare for an uncertain future, while continuously learning and improving transportation effectiveness. Taking a proactive stance enables shippers to gain a competitive edge as they plan, and replan with a new degree of agility and flexibility.

New-generation planning processes and technology solutions are allowing supply chain leaders to create an improved capability to predict and plan for their future transportation needs—by closely monitoring trends and preparing for capacity shifts. Intelligent strategies are helping them achieve their profitability and performance targets, even during periods of excess or short capacity. For example, if trends reveal that a capacity shortage is imminent, leading-edge shippers will be planning ahead and protecting their future performance by securing additional capacity through freight allocation techniques across a larger set of carriers.

Perhaps most important is the ability of these supply chain leaders to improve continuously through a closed-loop planning process that gathers—and addresses—the lessons of their historic results. While nearly every company measures its transportation performance in some quantitative fashion, only the leaders are examining the root causes of their performance shortfalls, and addressing the underlying reasons so that future results will be better.

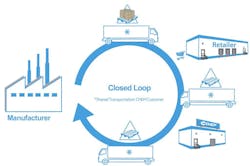

As shown in the diagram, “Closed-Loop Transportation Management,” effective transportation management is not a set of disparate activities, but instead is a closely knit, closed-loop set of processes. This closed loop is enabled by technology solutions, but must also include a well-managed set of business processes that ensure leading-edge technologies are leveraged in the most strategic manner.

The first step―modeling and analysis of the transportation network―feeds the procurement process by defining all the delivery costs, carriers and alternatives. The second step—the procurement of rates, service levels and capacity commitments—lays the foundation for execution. Tactical forecasts and carrier collaboration refine the constraints that must be honored as execution proceeds. Ongoing route planning and optimization should actively consider capacity restraints, as well as allow for dynamic replanning as conditions change. During the execution stage, technology solutions should enforce compliance, track performance capacity deficiencies and feed further analytics. One of the most critical steps in continuously improving transportation performance is the final one—conducting a causal analysis which asks and answers the key questions “What went wrong?” and “How can we do better next time?”

This six-step, closed-loop process has driven powerful results for some leading-edge companies whose key capabilities include shipping products.

Closing the Loop on Performance: Real-World Examples

PepsiCo is one example of an innovative enterprise that conducted a closed-loop analysis of its transportation capabilities and projected needs—and made a huge business shift as a result. During the causal analysis phase, PepsiCo recognized that one of its businesses, Frito-Lay, was managing one of the largest private transportation fleets in North America, and that this fleet was not fully utilized because it was managed on a narrow regional basis. Meanwhile, PepsiCo was spending large sums on commercial transportation for many of its other products.

By taking a strategic, problem-solving view, the company realized that many of its capacity challenges could be managed via its existing assets. Today, PepsiCo operates its own internal logistics and transportation division which shares resources across all of its diverse North American business—managed by a single technology solution and a set of common transportation planning practices.

Another consumer products leader, Kimberly-Clark, was faced with enormous shipping costs because its primary products—including diapers and paper towels—have large cube sizes, but relatively low price points. In fact, transportation costs represented approximately 6% of the company’s annual net sales. When conducting a causal analysis of its high transportation procurement costs, Kimberly-Clark executives recognized that the company needed to implement more flexible supplier relationships and minimize restrictive carrier contracts which fixed Kimberly-Clark’s transportation costs—whether trucks were empty or full, and whether capacity was plentiful or scarce.

Today, the business has saved millions of dollars by eliminating supplier contracts and using a flexible transportation solution that ranks all available carriers according to the lowest cost per route. During the procurement phase, contracts are automatically awarded to the lowest-priced carrier that can get products to stores on time.

As the second-largest North American manufacturer of kitchen and bath cabinetry—and with 95% of its products made to order—MasterBrand Cabinets also faces enormous transportation challenges. Because the company did not measure its budget and delivery performance for 30 to 45 days after shipment, MasterBrand was not able to analyze the cause-and-effect relationships in its transportation processes. In effect, it was completely missing the all-important causal analysis phase of the closed-loop transportation management process.

MasterBrand needed not only more timely data, but also an ability to understand how changes in one shipment or route would affect overall shipping costs and performance—allowing for continuous learning and performance improvement. MasterBrand implemented new planning processes and a technology solution that incorporates real-time data to provide visibility across all customer orders. Today, during the procurement phase orders are automatically routed to those carriers which balance the lowest costs with the highest service levels, ensuring continued profitability and customer satisfaction. The company also conducts root-cause analysis on a continuing basis. MasterBrand is subject to an especially high level of capacity fluctuation—but, with a new strategic perspective, has been able to keep its transportation costs per unit remarkably consistent.

Cyclical Needs Can Drive Continuous Rewards

No one can argue that it is difficult to manage transportation capacity in the face of shifting economic trends, volatile customer needs, quarterly deadlines and changing sales seasons. However, those supply chain leaders who are able to master the transportation capacity rollercoaster can turn their agility into a significant competitive advantage over companies who are still operating in a more reactive manner.

In adopting a more proactive and forward-looking capacity management strategy, shippers should focus on these keys to success:

● Share real-time demand visibility across the enterprise. Logistics and transportation represent complex activities that are based on one simple driver: customer demand. By focusing on real-time demand signals and sharing visibility across the business, your supply chain can recognize any obstacles to on-time fulfillment as early as possible—before they impact critical customer relationships or bottom-line profits.

● Leverage your existing assets to their greatest capacity. An upfront assessment of your internal and external transportation assets can yield surprising results. Is your business shipping full truckloads? Is your own fleet fully utilized? Are you combining orders in the most profitable manner? By looking at your existing investments, and maximizing their impact, your company can often avoid new transportation spending.

● Form more collaborative supplier relationships. Web-based technologies can help your business to partner more closely with suppliers, electronically sharing detailed purchasing, ordering, shipping and delivery information in real time. You can assess the actual, day-to-day performance of all your trading partners in order to continually improve relationships and results, as well as ensure that you are assigning shipments to the most lowest-cost, highest-service carriers.

● Be ready for the unexpected. While there will always be surprises, your business can prepare for unexpected capacity issues by running “what if” transportation scenarios and having tertiary carriers lined up in advance—so you can avoid paying premium shipping charges when capacity tightens. Executives can also minimize the surprise factor by taking a longer-term view and looking at market trends two or three years in advance, instead of managing on a quarter-by-quarter or other short-term basis.

● Learn from your mistakes. A critical transportation management capability is implementing a closed-loop process that enables your business to assess what went wrong in your historical performance—and apply these lessons in the future. It’s never enough to measure numerical performance and set new targets randomly; your business must address the root causes of any shortfalls in order to ensure that the same mistakes won’t happen again. To be truly effective, transportation management must consist of a closely knit, closed-loop set of standardized processes focused on planning, executing, assessing results at a granular level and adjusting the plan in real time.

Of course, the ultimate success factor is making the decision to proactively attack the capacity challenge by leveraging new tools and processes to make more strategic long-term decisions, instead of scrambling to implement short-term tactics that may or may not have a sound business foundation.

Every company is going to be affected by seasonal or quarterly deadlines, the rise and fall of the economy, changing carrier availability and shifting customer preferences. But the extent to which your business is impacted can vary greatly, depending on the preparations you’ve made and your ability to respond agilely to any performance issues. If your enterprise can take a long-term view and establish a culture of continuous learning, you may be able to leverage sudden capacity shifts as a meaningful advantage over competitors who are less prepared. Taking a proactive, rather than a reactive, approach is what ultimately separates the leaders—those who can master the capacity rollercoaster — from all others.

Fabrizio Brasca is vice president, global logistics with JDA Software. He is responsible for developing transportation and logistics strategies across all industry verticals.