The Future of Logistics Rests on the Shoulders of the Internet of Things

According to a recent collaborative report by DHL and Cisco, there will be 50 billion devices connected to the Internet by 2020 compared to 15 billion today. Furthermore, the Internet of Things (IoT) is expected to generate $8 trillion worldwide in "value at stake" over the next decade, defined as the economic value brought about by connecting previously unconnected devices.

The industrial sector is leading the way for this explosion of connected devices. In fact, according to consulting firm Accenture, the Industrial Internet of Things is a major trend with significant implications for the global economy, and Accenture estimates that the Industrial IoT could add more than $10 trillion to the global economy by 2030.

Although the forecasts for how large the IoT market will be range widely in terms of how many tens of billions of devices will be connected or how many trillions of dollars' worth of value will be created, one thing is clear: IoT will be a game changer. And global firms agree. According to a recent survey conducted by Forrester Research, over 80% of global firms agree that IoT solutions will be the most strategic technology initiative for their organization in a decade. On a global scale, new digital infrastructures will be required to enable physical and digital services to create "smart services." These infrastructures will play a critical role in the transformation of our economy and society.

How the IoT Changes the Game

Companies have been using sensors and networks to get information about the condition of equipment for more than 20 years. But they were individual, closed systems, not connected to IT and other operational systems. Today, the cloud enables the storage and processing of large volumes of data which, when combined with analytics software, enables companies to manage and extract useful information quickly and cost effectively—finally connecting these historically siloed systems.

Furthermore, exponential improvements in the miniaturization and cost of sensors, microprocessors, memory and communications have driven rapid adoption of increasingly intelligent connected devices.

What capabilities are possible when companies strategically deploy a large network of intelligent connected devices? In a November 2014 Harvard Business Review article, Michael Porter and James Heppelmann grouped IoT capabilities into four areas, each building on the preceding one (see Figure 1).

Asset Management and Security are Driving the IoT

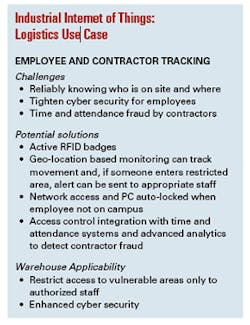

The top two areas in which businesses are deploying the IoT are in asset management and security.

Firms want to locate high value assets, monitor their condition and optimize their utilization to drive efficiency. They also want to secure their whole supply chain by responding to alerts in real time and proactively addressing threats to the integrity of their supply chain to protect their employees, products, consumers and ultimately their company reputation.

Examples of how IoT applications can address asset management and security to improve material handling and logistics include:

Optimization: Industrial machines equipped with vibration, energy usage and temperature sensors sending data captured by analytics software can predict and schedule preventive maintenance to minimize downtime and costly repairs.

Autonomy: Active RFID combined with location sensors can reliably determine "on presence" identification of employees, immediately send alerts if someone enters a restricted area and when they leave, automatically lock office PCs and restrict network access.

Integrated technologies like the above can correlate relevant information and incidents from multiple systems and apply corporate policy to enforce consistent actions across the organization, driving corporate and regulatory compliance.

The Bottom Line

In order to remain competitive in an era of evolving global consumer security expectations, companies will need to introduce integrated intelligence into products and processes. With the IoT already taking shape, companies can build upon this foundation of connections to capture data from multiple sources in real time. Security and operational employees can then integrate and analyze this aggregated data to effectively identify actionable insights, thereby improving operations and better protecting employees, customers and company assets.

Don Hsieh is director of commercial and industrial marketing with Tyco Integrated Security (www.tycois.com).