The appropriate metrics to manage and measure the success of a company’s operation vary significantly by industry, by individual company, and by the scale of the business. What does not vary, however, is the universal need of all companies to employ a well-structured, hierarchical framework to organize and manage their metrics.

The absence of a cohesive framework to house metrics greatly increases the likelihood that a company’s performance measurement system (PMS) will provide inadequate management support, and that resources will be wasted developing duplicative, unaligned and even conflicting metrics.

There are a number of well-known models and frameworks for operations, logistics and supply chain management. Two of the most prominent are the SCOR model and the Balanced Scorecard, and the interested reader is referred to these.

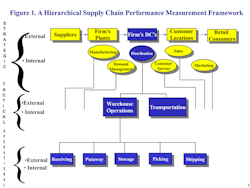

Figure 1 depicts an integrated hierarchical supply chain performance measurement system. The framework contains three levels (the strategic, tactical and operational), and within each level, it has both external and internal measures. In this PMS framework, it is the scale of an operation or activity that a particular metric monitors which determines its place in the hierarchy.

As we observe in Figure 1, metrics that measure the performance of an entire major functional area (such as distribution) are considered strategic, while metrics that monitor major sub-functions (such as warehouse operations and transportation) are categorized as tactical, and finally metrics that monitor sub-functions of sub-functions (e.g., the receiving operation in a warehouse) are considered operational metrics. One can adapt this PMS framework to as many or as few echelons as may exist in your company’s supply chain.

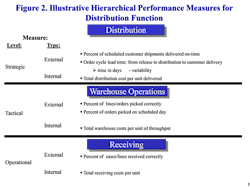

Figure 2 provides additional insight on how this hierarchical PMS framework works, displaying sample external and internal metrics for a distribution organization at each level of the hierarchy. The external metrics measure outputs and/or services that flow across the supply chain and evaluate some aspect of serving the customer. The internal metrics have an “inward” focus; and as shown in Figure 2, they evaluate how efficiently the overall distribution organization and each of its sub-functions operates.

Employing a hierarchical performance measurement framework offers a number of important benefits. First of all, this approach provides a unified framework for aggregating performance metrics across a company. By implementing a hierarchical measurement approach, a company positions itself to organize its key performance measurements into a structure that leads to a relatively few, high-level, strategic measures (e.g., between 10 and 25) that monitor overall corporate performance. At the same time, this structure facilitates having many other performance measures that monitor smaller components of a company’s operation, yet which align with overall objectives. In particular, a hierarchical measurement system allows both large and small functional areas within a company to:

- develop and maintain their own measures, and

- contribute to and be part of an overall measurement system.

This hierarchical approach thus helps to keep measures both simple and meaningful because each function and sub-function at each level can focus on a few key performance measures.

Finally, a hierarchical performance measurement system can also contribute towards aligning the collective activities of a company to meet a desired mission and set of objectives. For example, if a company has a comprehensive measurement system in place that covers most or all of its major functional areas and activities, managers can view the system in its entirety to identify any potential misaligned activities or objectives.

Tan Miller is director of the Global Supply Chain Management Program at Rider University, College of Business Administration, and is a member of MH&L’s Editorial Advisory Board. Previously he worked in private industry for over 20 years where most recently he was responsible for the operations of J&J’s U.S. Consumer Distribution Network.

About the Author

Tan Miller

Director, Supply Chain Management Program

Dr. Tan Miller is director of the Global Supply Chain Management Program at Rider University, College of Business Administration. His responsibilities at Rider include advising students in the GSCM Program, teaching introductory and advanced courses on supply chain management, and directing ongoing enhancements to the GSCM curriculum. Previously he worked in private industry for over 20 years where most recently he was responsible for the operations of J&J’s U.S. Consumer Distribution Network. Prior to that, he headed the U.S. Consumer Healthcare Logistics Network of Pfizer Inc., and he has also held production and distribution management positions with Mercer Management Consulting, Unisys, Warner-Lambert and American Olean Tile Company. Miller has published five books and over fifty articles, and has made over 100 industry and academic conference presentations on supply chain and logistics operations and planning. His most recent books include Supply Chain Planning: Practical Frameworks for Superior Performance (Business Expert Press), Hierarchical Operations and Supply Chain Planning (Springer-Verlag Publishers) and Strategic Logistics: Efficient Transportation Decisions (Boskage Commerce Publications). Miller has also taught part-time in the MBA program of Villanova University, has guest lectured regularly at other universities and industry conferences, and has served on the editorial and advisory boards of a number of trade and educational journals and councils. Tan received an M.A, M.B.A and Ph.D from the University of Pennsylvania.