Policymakers, both nationally and on the state level, should consider local institutional investments in the deployment of 3-D technology for optimal advanced manufacturing cluster formation, according to a recent report from the MAPI Foundation, the research affiliate of the Manufacturers Alliance for Productivity and Innovation.

The industry group noted that the flexibility of production and the capacity of 3-D printers to produce proximate to the point of input are already beginning to shorten supply chains in a number of industry sectors, a considerable boon for the cost and efficiency of goods production.

Cliff Waldman, MAPI Foundation director of economic studies finds that of all the revolutionary capital available to the manufacturing sector, 3-D has the most potential to fundamentally alter business models in that it can shape processes and products.

For existing supply chains, 3-D technology can give the end-user the capacity to participate in the innovation process. Commensurately, as printers fall in cost and capabilities are more widely understood by the public, they can stimulate much-needed manufacturing-related entrepreneurship.

"Over time," Waldman notes, "certain goods-producing sectors will be populated by small but disruptive competitors, a plus for the growth and global responsiveness of U.S. manufacturing."

The growth of 3-D deployment has been remarkable. During 2008, there were 355 commercial printing machines in use worldwide. By 2013, that number grew to 23,000.

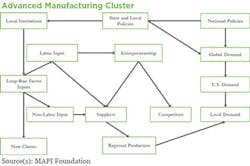

Using a cluster model developed at the MAPI Foundation (below), Waldman concludes that 3-D technology will be a driver of regional manufacturing competitiveness. Smaller and more agile industries will allow for specialization in some aspect of 3D-driven new product development. Hence, product design in certain manufacturing industries will become a more prominent part of supply chains and therefore of clusters.

"The new manufacturing production paradigm in general and the contribution of 3D specifically have the potential to drive regional manufacturing systems toward ever-higher levels of efficiency, innovation, and competitiveness," Waldman said. "With its capacity toward flexible design, 3D printing will have the possibility to provide cluster-to-cluster spillover impacts and the development of new clusters. This will result in a major boost to the strength of U.S. manufacturing.

"The emergence of 3D processes will mean regional advanced manufacturing ecosystems will change—and change fairly dramatically. Thoughtful investments in that powerful new technology can provide a very high return," he concluded.