By Paul Husby

Four supply-chain improvement methodologies widely used across the United States—SCOR, Lean, Six Sigma and Theory of Constraints— have proven themselves by generating cost and cash results for many companies. The key to success is commitment and belief in the methodology practiced, often resulting in a strong emotional investment by practitioners.

Frequently practitioners come to believe the approach they've selected is better than other methodologies because their results reinforce their belief. Are these methodologies really competing? Is it possible each has unique strengths and limitations the others don't have? What differentiates success from failure in improvement methodology implementation? This is the first of a three-part series exploring and answering these questions.

What is SCOR?

In 1996 supply-chain consulting firm Pittiglio Rabin Todd & McGrath (PRTM, www.prtm.com) and AMR Research (www.amrresearch.com) introduced the Supply Chain Operations Reference Model (SCOR) and founded the Supply Chain Council (SCC, www.supply-chain.org), a user-based organization that owns the SCOR intellectual property. The council started with 69 member companies and has grown to more than 700.

The SCOR model was developed to understand, describe and evaluate supply chains. The SCOR approach differs from Lean and Six Sigma in that SCOR is focused on evaluation only. It identifies specific best practices to improve supply chains. The model does not include project implementation, assuming users are competent at project implementation and supply chain practices. The SCOR approach:

1. Describes the unique set of customer-driven priorities of individual supply chains;

2. Quickly identifies performance gaps through benchmarking;

3. Eliminates analysis time and effort through predefined cause and effect relationships embedded in the model's multi-level decomposition structure;

4. Provides solutions to closing performance gaps through best practices;

5. Defines enablers (including information technology) required to support best practices.

The SCOR top-down supply chain assessment methodology defines a supply chain as the integrated processes of Plan, Source, Make, Deliver, and Return. From the supplier's supplier to the customer's customer it spans the value-adding processes for suppliers, internal operations and customers.

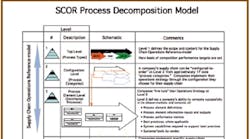

The SCOR model decomposes the five Level 1 processes in Level 2, allowing the user to define the configuration of their supply chain, whether it's make-to-stock, make-toorder, or engineer-to-order. Defining the configuration is important to insure the relevance of benchmarking data.

Level 3 defines processes (how work is done), which include metrics, a series of practices and enabling technology tools. Level 1 and Level 2 performance metrics link directly to Level 3 metrics facilitating the identification of the Level 3 processes which explain Level 1 performance.

Level 4 defines specific tasks of Level 3 processes. These specific tasks are uniquely configured by the company. SCOR excludes level 4 from the model because it is specific to each business, making standardization difficult.

Benchmarking

To start benchmarking, current supply chain performance is documented using SCOR Level 1 metrics (see SCOR Benchmarking Summary). The supply chain metrics are divided into customer-facing and internalfacing categories. These standardized metrics facilitate external benchmarking using sources available through the Supply Chain Council.

Benchmarking compares your company's performance with peer companies in the same markets or with companies from other markets with leading supply chain practices. The findings are presented in a SCOR benchmarking summary. A company's current performance is noted on the summary for all categories and then compared to the median, the 75th percentile (advantage) and the 90th percentile (best-in-class). The quantification of performance gaps allows potential benefits to be estimated, forming a business case for justifying investments required to make the practice changes.

Diagnosis and creating the vision

When Level 1 performance gaps have been defined the diagnostic phase begins. Since SCOR Level 1 and Level 2 metrics link directly to Level 3 metrics and practices, potential root causes of performance gaps can be confidently identified. Benchmark comparisons at Level 3 identify specific current process performance as better than, equal to or worse than benchmark. The diagnosis also compares current versus best practices, defining the changes needed to close the performance gap. Level-to-level metric links insure identified best practices will resolve root causes of gaps.

Suppose Level 1 benchmarking showed inventory days of supply as a large performance gap. During the diagnosis phase Plan Level 3 practices and their corresponding metrics are examined (see Plan Level 2 and 3 metrics).

This same benchmarking process is done for Level 3 Source, Make and Deliver processes to identify additional practice changes required to close the inventory days of supply gap. The vision is created at this stage by defining specific improvement goals: 1) The Level 1 performance goals directly connected to improving the basis of competition for the business; 2) Definition of the supply chain configuration; and 3) Identification of best practices to be implemented.

SCOR gives a perspective of all processes required for design and improvement of supply chains not provided by Lean, TOC or Six Sigma. SCOR should be the starting point for improving any supply chain, insuring projects are connected to business strategy and improving operational competitive advantage. The Supply Chain Council website is an excellent resource for in-depth information about SCOR, available training and membership in the Supply Chain Council. Another valuable resource for SCOR assessment and improvement is Supply Chain Excellence (Amacom, 2003) by Peter Bolsdorf and Robert Rosenbaum, two experienced SCOR practitioners.

Paul Husby recently completed a 38-year career with 3M, including managing director of 3M Brazil, division vice president of the Abrasives division, and corporate staff vice president of manufacturing and supply chain services. He practiced all four of the methodologies during his career. SCOR was used in 2004 to assess 3M processes and develop a direction for improvement. Lean was implemented in all 3M plants worldwide as one of the initiatives from SCOR benchmarking. Husby is a certified Six Sigma Champion with five years of successful application at 3M. As the managing director of 3M Brazil, TOC was utilized in all plants and made significant contributions to the business. Comments and critiques are welcome ([email protected]).

| SCOR Strengths and Limitations Strengths: SCOR limitations: |

The SCOR model's five integrated processes include: Plan (balancing needs against resources, Source (processes connecting the manufacturer to suppliers), Make (changing the form, fit or function of something), Deliver (Processes connecting manufacturers to customers) and Return (Processes connecting the return of products for any reason).

This example was designed for a particular customer and includes a financial benefit summary along with the SCOR Level 1 metrics.